If you outsource any product from China, you’re probably familiar with Chinese New Year, also known as CNY. Perhaps your supply chain has even experienced CNY before. If so, you know that Chinese New Year is in a class by itself when it comes to preparing for production and shipping disruptions. If this Chinese New Year will be your first rodeo, let us help keep your supply chain on track while minimizing any negative impacts.

Chinese New Year will begin on February 10, 2024. Typically, Chinese offices and factories close for about three working weeks, allowing workers time to travel back home to spend the holiday with their families. To get a better idea of how large the migration movement during the Chinese New Year holiday, Baidu, which is often referred to as China’s version of Google, released an interactive map tracking the migration patterns around the country. Here’s the migration map from 2015:

In 2015, an estimated 80 million workers, the majority in urban areas along China’s coast, traveled by road, train, and plane back to their rural hometowns during CNY. The massive holiday migration goes back to the late 1970s when economic reforms caused extraordinary growth in cities in coastal regions of China, especially in the cities of Shenzhen, Xiamen, Shantou, and Zhuhai. Rural Chinese, looking for a stable paycheck, moved to cities hundreds of miles from home. But just like in the U.S., holidays are considered family time and the Chinese business calendar reflects that.

What Does Chinese New Year Mean for You?

Maybe you’re halfway around the world wondering why you should be mindful of and plan for the largest Chinese holiday of the year. Grab your calendar and follow along.

Although CNY officially only lasts for one week, many factories and businesses shut down about 10 days before CNY to allow time for workers to travel home. There is always a mad rush to ship product out of ports before the country shuts down. This can lead to increased freight costs and longer transit times if there is a delay at the port or a container is not loaded on its intended vessel.

Don’t forget to account for travel time back to the city. In all, the holiday can disrupt production and shipping schedules for up to three weeks or more. Interestingly, the CNY holiday is also considered a prime time to switch jobs, and many workers don’t return to work at all. This can lead to even longer production times as factories struggle to find new workers and ramp up on production orders.

Since China is an economic giant in the global exporting industry, the effects of CNY can ripple around the world, especially for retailers and anyone else who relies on imports from China.

How to Plan for Chinese New Year

What can you do to keep your supply chain running smoothly when one of the world’s largest exporters shuts down for nearly a month? We’ve outlined 10 tips to proactively plan for Chinese New Year to minimize any disruptions to your supply chain:

1. Understand what happens during CNY

In the United States, it’s hard to fathom our businesses shutting down for three weeks or more. Sure, some of us take nice long vacations for the holidays, but there’s a good chance our offices are still open while we’re gone. Once you understand that China shuts down nearly everything for CNY and nothing, absolutely nothing will get out of China during that time, the better you can plan. Your orders need to ship prior to CNY and don’t forget to plan for inventory needed to get you through the holiday. There is no way to avoid CNY — it happens every year (albeit on different dates) and it requires advanced planning to minimize interruptions on your end.

2. Develop a trusting relationship with your supplier or manufacturer

There are few things as valuable as establishing a strong relationship with your China supplier or manufacturing partner early on. If you’re sourcing from China and just beginning to build your supplier network, it will be difficult to build that relationship in the months immediately prior to CNY. There is immense pressure on Chinese factories right before CNY, and if your business is the newest account at the factory, it’s likely that your goods will be their last priority when it comes to order completion and shipping pre-CNY. If you’re working with a manufacturing partner, ensure that they have experience handling the CNY crush. Ask what measures they have in place to help their customers plan for CNY. One of the advantages of working with a manufacturing partner is that they usually have years of experience building a trustworthy supplier network and can help ensure your product is shipped on time during the hectic holiday rush.

3. Create a forecast to get you through CNY and beyond

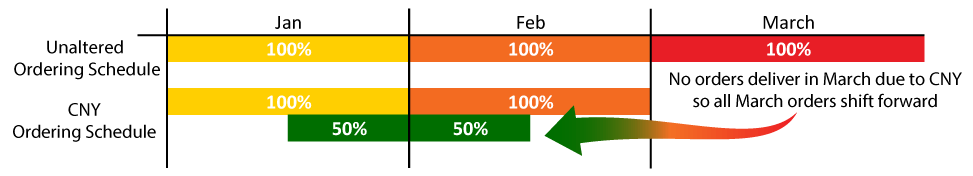

If you’re able to forecast how much product you’ll need for the first 3 to 4 months of the next year, you’ll have a leg up on ensuring your company has enough stock on hand to last you through CNY. We’ve created this simple rule to help account for CNY delays:

- For orders normally received in March, take 50% of the volume and receive it in January. Receive the other 50% of that volume in February.

Another great advantage of providing a forecast to your supplier or manufacturing partner is that the factory will be able to see your demand after CNY so the factory can begin recruiting and training workers earlier, already knowing that a portion of their staff will not return.

4. Increase your inventory beforehand

That forecast you created for our last tip will come in handy for this advice as well. If you already know how much product you’ll need for the first part of next year, you could begin to order a little more product now to account for the lack of orders to be received in March of next year to hold in inventory. An accurate forecast and previous sales history will be beneficial to keep inventory at manageable levels and ensure you don’t over-order product.

5. Deliver cargo to the port no later than 10 days before the ship date

If you’re responsible for arranging your own logistics from China to your company or customer’s door, book shipments with steamship lines well in advance of CNY. Steamship lines are notorious for taking advantage of the Chinese New Year situation when there is an abundance of shipments waiting to leave port before everything shuts down. Steamship lines often impose large freight rate increases during this time, as the demand to get on board a cargo ship is high, and those who can afford to pay the higher cost will leave the port on time. It’s not uncommon to hear of containers getting rolled to the next booking during the weeks leading up to CNY; this means the container gets bumped to the next available vessel leaving port. Depending on how often a container gets rolled, this could mean days or weeks of delays. Here is where another trusted relationship with a freight forwarder or manufacturing partner will come in handy as many work with shipping lines that are more organized and better prepared to deal with the peak demand of CNY.

6. Don’t put all of your eggs in one basket

Consider working with a manufacturer who has operations in countries other than China. Not only will this help diversify your supply chain, but it’s possible your manufacturer could find a backup supplier if needed during the Chinese holiday. Some products are made of components from various countries which helps alleviate the pressure of one factory doing all the work. For example, components could be sourced from China, and then shipped to Vietnam for assembly and packaging. Keep in mind that Vietnam also celebrates its Lunar New Year holiday, called Tet, on the same day as Chinese New Year. However, Tet usually only lasts for one week, at most. The Tet effect is nowhere near as sizable as Chinese New Year, but factories and businesses still shut down for a week to allow workers to spend time with their families.

7. Put a Quality Management Plan into place

The last thing you want is for an order of goods that has quality issues to ship right before CNY. Sometimes quality can take a back seat as the factory is producing in high gear and is in a rush to get product out the door. This is yet another time when a trusted supplier or manufacturer relationship will help tremendously. Having a quality management and thorough inspection plan in place will drastically reduce the risks of a delayed shipment due to quality issues, or worse, shipping defective goods to your customer’s door.

8. Take advantage of Vendor-Managed Inventory

Vendor-Managed Inventory (VMI) is a business model that allows a vendor and a buyer to maintain an agreed level of inventory for a product. The vendor will ensure the required inventory level is maintained by ordering more efficiently and adjusting for seasonal demand and shifts in the market, helping to reduce the cost for the buyer. Your vendor will normally need your sales history and current inventory on hand to forecast your demand and develop an ordering schedule. VMI is ideal for those who find long lead times challenging and to deal with holidays like CNY, which could wreak havoc on a supply chain without proper planning.

9. Plan for AFTER Chinese New Year

Remember earlier when we mentioned that not all the factory workers will return to their old jobs after CNY? You don’t just need to plan for before the holiday, but afterward as well. If there’s a workforce shortage, it could take weeks, sometimes months, for the factory to get back up to normal production speed as they look for replacement workers. Having the forecast we mentioned or increased inventory on hand should help tide you over until the factories are producing at full capacity again.

10. Start planning early

It’s never too early to start planning for China’s biggest holiday. The earlier you begin, the better your supply chain will be. Analyze your sales history from the past year, start putting a forecast together, and work with your suppliers and manufacturing partners now to begin planning for the upcoming Chinese holiday.

Knowing what to expect during CNY is only half the battle. Being well-prepared is the best way to alleviate any negative impact on your supply chain. We hope these 10 tips reduce the CNY stress and contribute to a successful plan and smooth sailing through the next Chinese New Year.

Plan Ahead for Other Chinese Holidays

Chinese New Year may be the biggest holiday but there are actually several other Chinese holidays that could have an effect on your business. Below are the upcoming 2024 dates for the additional Chinese holidays:

- Qing Ming Jie (Tomb Sweeping Day) - Thursday, April 4th

- International Labor Day - Wednesday, May 1st

- Dragon Boat Festival - Monday, June 10th

- Mid-Autumn Festival/Moon Festival - Tuesday, September 17th

- Golden Week Holiday - Tuesday, October 1st - Monday, October 7th

East West Customers

For customers of East West, we recommend any forecast or Purchase Order changes are communicated to us by October 1, 2023, to ensure we can implement the necessary strategies to keep your supply chain full over the CNY period.

For those customers taking releases from East West's warehoused inventory against blanket Purchase Orders, we will automatically manage our inventory to minimize any CNY impact. We only ask that you provide us with an updated forecast through the month of March.

Please reach out to your dedicated East West Customer Account Analyst if you have any questions about planning for CNY 2024.