Looking to learn more about the different types of motors out there and which one may be right for your business? Here is a brief rundown on the three most popular types.

Shaded Pole Motor

- The cheapest motor due to the older design and technology

- Typically used for light ventilation applications

- The least efficient motor because it generates the most heat versus power applied

- Around 30% efficiency

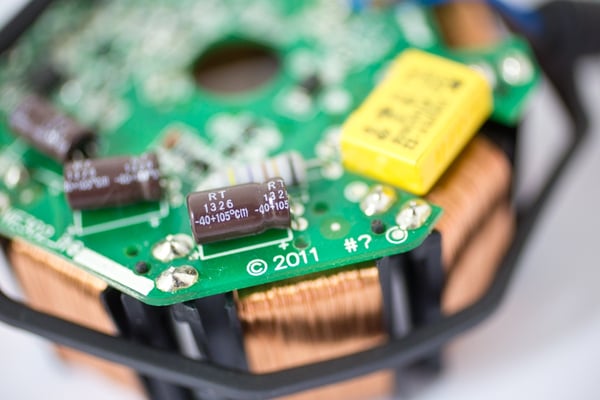

PSC (Permanent Split Capacitor) Motor

- Most commonly used motor

- A capacitor is usually used to help run the motor and generate more torque

- These motors can run either single or multiple speeds.

- A PSC motor is usually 40-60% efficient, meaning you're only going to get about 40-60% output power from the motor

EC (Electrically Commutated) Motor

- The smartest motor currently available

- More expensive motor but you gain high efficiency

- Typically has a printed circuit board inside to get feedback on its environment

- 70-82% efficient and can see ROI within a year

- For more information on EC motors, check out our basic guide.

Curious to see if EC motors are right for you? Download our free case study here.

The U.S. Department of Energy has finalized new legislation for businesses in the refrigeration industry that could affect a large number of businesses. The new regulations are due to take effect in 2017. Download our free eBook below to read the 5 takeaways you need to know in order for your business to meet the new DOE standards.

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)