It's a question for the ages...What's the difference between a Permanent Split Capacitor (PSC) motor and an Electronically Commutated Motor, also known as an EC Motor or ECM?

(Okay, maybe not a question for the ages, but it's an important question.)

A PSC motor is a commonly used motor that runs at either single or variable speeds, while an EC motor is much more energy-efficient and features an internal smart board offering better motor control. Using EC motors holds three clear advantages over the use of PSC motors.

Advantages of EC Motors

1. VERSATILITY

One EC motor can be used in numerous applications. It could take up to three to four SKUs of different PSC motors to fill the same applications that it would take one EC motor to fill.

2. PROGRAMMABILITY

Using an internal smart board, the EC motor can be programmed with multiple inputs to vary speed and voltages.

3. EFFICIENCY

We are using conservative figures, but EC motors are usually 70 percent more energy efficient than a single PSC motor. They also meet the U.S. Department of Energy's standards for energy efficiency.

Those three advantages — versatility, programmability and efficiency — make EC motors an ideal choice for use in applications where a steady, constant working motor is essential for operations, for example, commercial refrigeration products like refrigerators, freezers, bottle/reach-in coolers in vending equipment, supermarkets, restaurants, commercial kitchens and convenience stores.

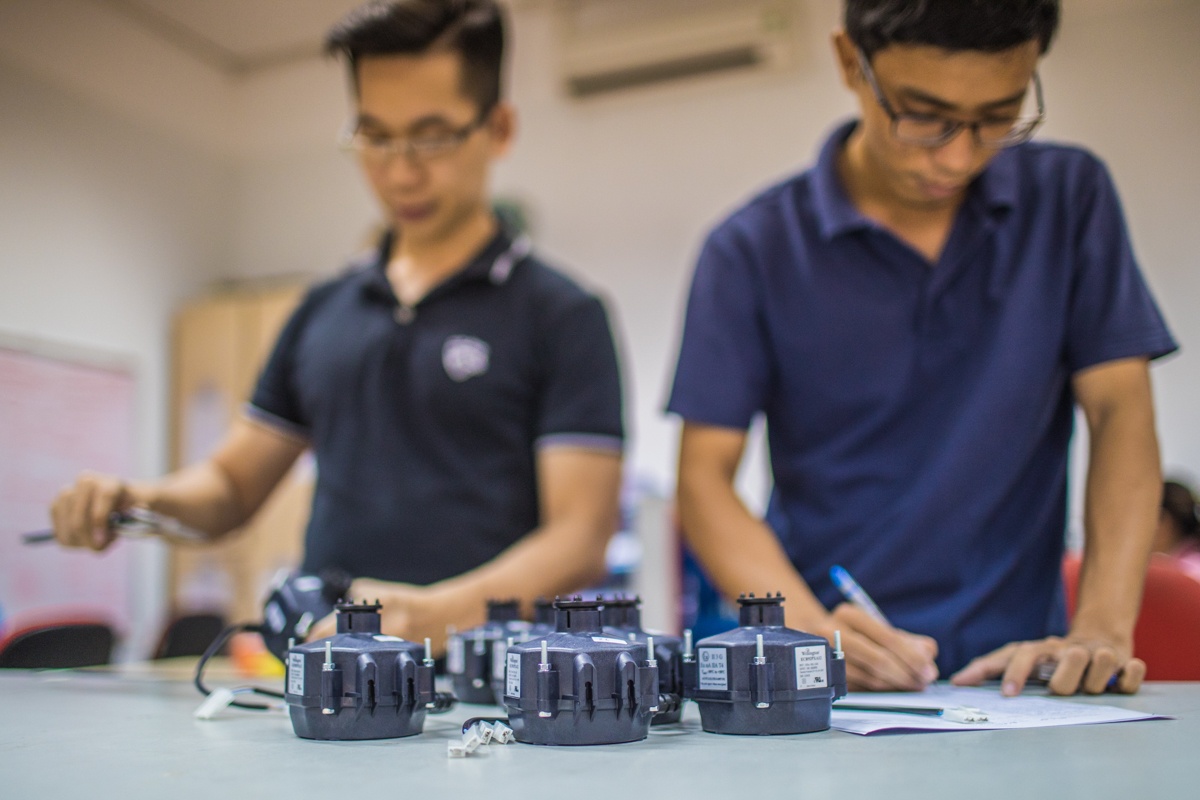

Better Materials Make Better Motors

One reason for the improved performance of EC motors is the use of improved materials. Advanced plastics, like glass-filled nylon resins, are used as replacement materials for steel and aluminum throughout the motor either as insulation material, structural parts or enclosures. These sturdy plastics — the strongest, non-commodity plastic readily available — are the perfect material for high efficiency EC motors.

8 Ways Using Plastic Enhances Performance of EC Motors

1. Thermal Insulation

Metals are great thermal conductors, making them effective at transferring waste heat from a motor to the outside atmosphere. This is a valuable asset in high-powered or low-efficiency motors as both create large amounts of waste heat that need to be dispersed.

But in small energy-saving EC motors there is very little waste heat and no real need to encourage heat transfer. Using plastic housing slows heat transfer and provides a more stable environment inside the motor (protecting the bearings and electronics from thermal shocks and extreme low temperatures) and outside the motor (improving temperature control).

2. Low Temperature Tolerance

Selecting the correct material is critical for commercial refrigeration and other low temperature applications, as some metals (including most steels) and many plastics become brittle below about -10°C (14°F).

Rated for low temperature use, advanced plastics, retain over 80 percent of their impact strength at -30°C (-22°F). Thermal insulation properties of plastics are also helpful at low temperatures because they allow the motor to warm up, preventing it from being exposed to long periods of vibration while extremely cold. Lower vibration means quieter motors.

3. High Temperature Tolerance

The most commonly used metals can tolerate temperatures far above what is encountered in motors, but very few plastics can operate effectively under extreme temperatures.

However, there are a variety of advanced plastics available which will withstand the temperatures found in EC motors. Look for grades of plastic that are UL-rated for normal operating temperatures up to 155°C or 311°F (Class F).

4. Electrical Insulation

Because ground connections are required to maintain safety when metal is used, motors can become compromised by connections that are incorrectly fitted or corroded.

Using an advanced plastic for housing and rotor hubs allows some EC motors to meet double insulated standards and avoids the need for a ground connection, while keeping installation and maintenance personnel safe.

5. Corrosion

Constant temperature swings and moisture found in refrigeration systems are deadly to motors. Those environments lead to corrosion, a frequent culprit in motor failure. Even normally non-corrosive materials like aluminum can break down from the harsh conditions found in many refrigeration systems. Corrosion is made even worse by combining several metals, such as steel laminations and bearings with aluminum housings (known as electrolytic corrosion).

The good news is that plastics do not corrode. And since they are electrical insulators, they also keep electrolytic corrosion between metal parts from occurring, avoiding motor failures entirely.

6. Vibration and Sound Isolation

Metals are hard and rigid. With constant movement, they vibrate, even slightly. Combine that with impact on other parts and you've got constant noise. Vibration and impact also cause wear and tear on parts.

Plastics are less stiff than metals and because of their natural properties have some internal damping. This minimizes the transmission of motor-generated sound and vibration, particularly high frequency noises. It also helps protect internal components from shock and impact.

7. Flammability

High operating temperatures mean only fire-retardant grades of engineering plastics can be used in these motors. There are several levels of fire retardance as defined by international standards, the highest are V-0 and 5-V.

8. Strength

Most of us think that metals are normally stronger than plastics. However, with modern engineering plastics, the difference can be minimal. For example, glass-reinforced nylons can have a failure stress of over 200MPa, which is similar to the yield strength of common aluminum alloys and cast or wrought irons.

Additional points to remember:

- Most EC motors on the market have converted to plastic housings and some internal components.

- Beware! All plastics are not the same and you need to ask the tough questions on the front end.

- Make sure your manufacturer is transparent and knowledgeable.

- Don’t be afraid to ask what types of plastic they use to make their motors. If they don’t know, keep looking!

In fact, if you're on the hunt for a motor supplier, you don't want to miss our blog post: Questions to Ask an EC Motor Supplier.

Read more:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)