Hindsight is 20/20. We’ve all heard that adage. But what if hindsight could become foresight?

Product quality issues can be a real pain to deal with, but one thing is for sure: quality issues are inevitable, no matter how experienced your supplier is. So knowing how to address such problems is a skill worth learning. Of course, some issues will be more substantial than others, but approaching them with purpose and patience is the best way...

Quality and cost are two of the top criteria most companies look at when seeking a contract manufacturer. The reasons are obvious. If your product doesn’t meet the definition of quality — defined by industry standards or the consumer — your product is doomed to failure. Every product development project — whether a new product or changes to an...

Third party testing and certification is one of the most important and expensive decisions you'll make in the product development process.Certification marks — whether UL, ETL or some other entity — demonstrate that the testing facility has tested samples of the product and found that it met that entities' requirements. The mark guarantees the...

Here’s the scenario: You have a part that you’ve been making and selling but you’ve decided to put it out to quote. You send your drawings package and samples of the part to a contract manufacturer that has a reputation for providing quality engineering support. In reviewing the drawings, the project engineer picks up on a small but significant...

Rework happens.

In fact, a 2013 study by the Lenox Institute of Technology of more than 100 industrial metal-cutting operations found that, “regardless of the percentage of machine uptime reported, respondents admitted that finished products don’t pass first inspection 20% of the time and require rework.”

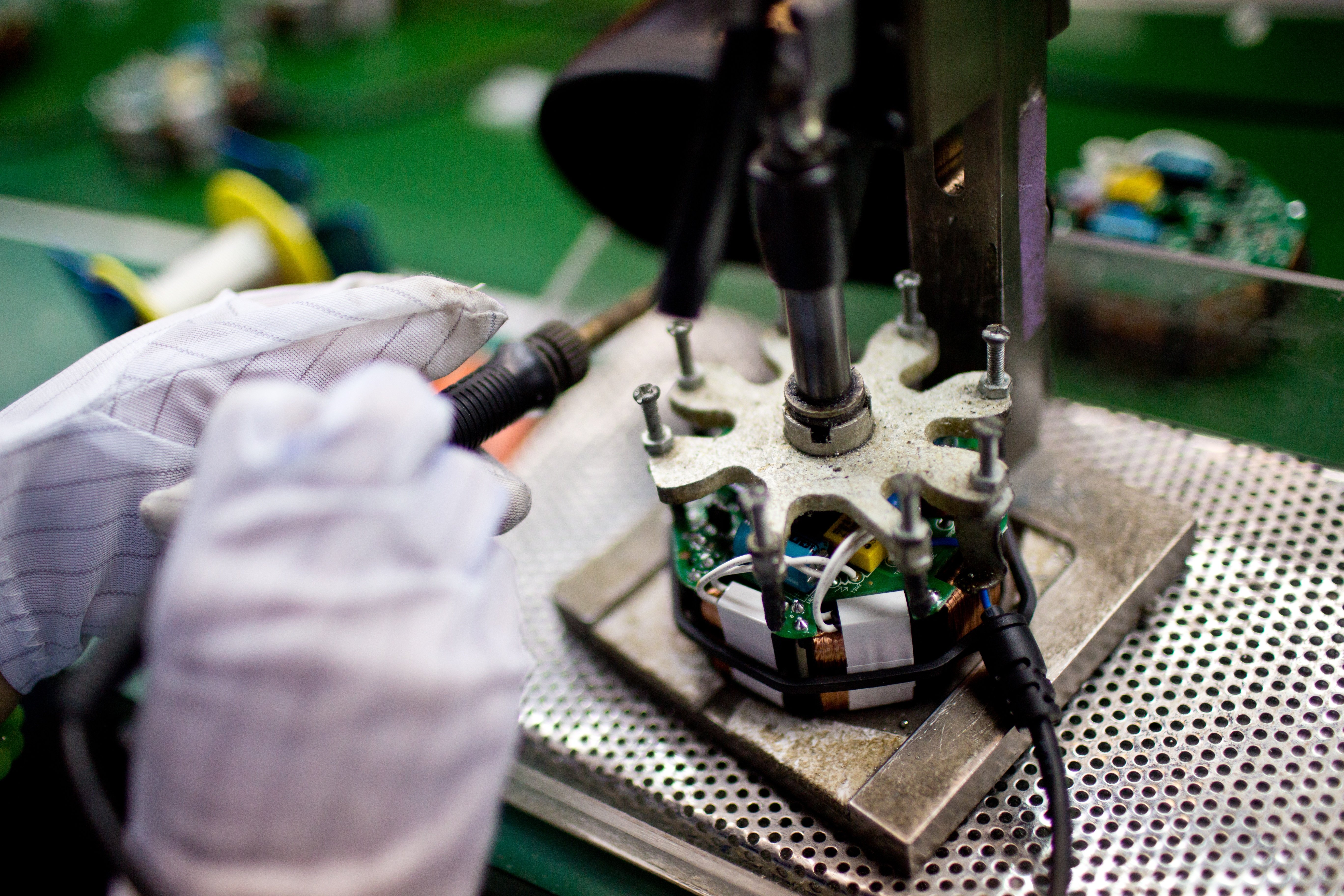

Motor Reliability Testing: Does Your Contract Manufacturer Stack Up?

Normally at the start of a manufacturing relationship, the contract manufacturer will ask the customer for a spec sheet — a report showing a variety of acceptable tolerances for the part or product. But if it’s a new product, or an older product that has undergone tweaks or changes through the years, there might not be a neat, up-to-date report.

...

You've probably been told that it's alright to make a mistake as long as you learn from it. This is something we preach here at East West. While mistakes do happen, some can be very costly and chip away at your bottom line (something our CFO likes to avoid). One such example is accumulating costs from rework, which is the correcting of a...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)