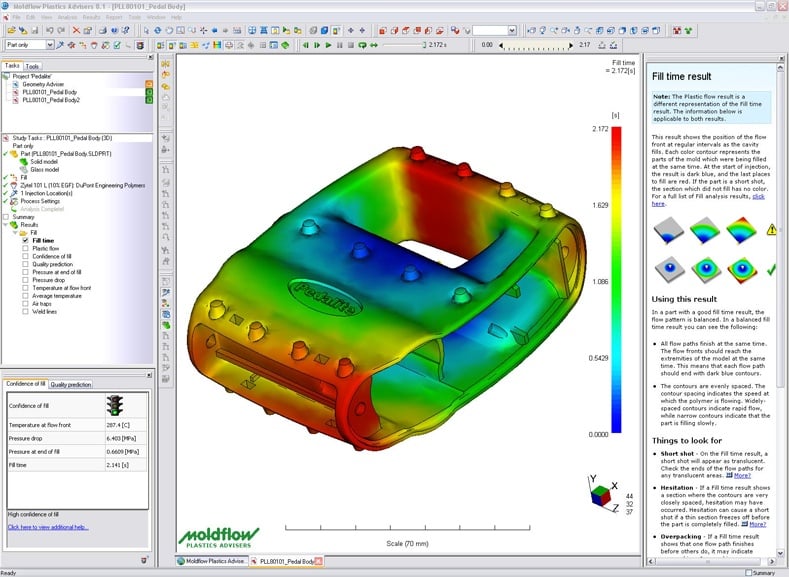

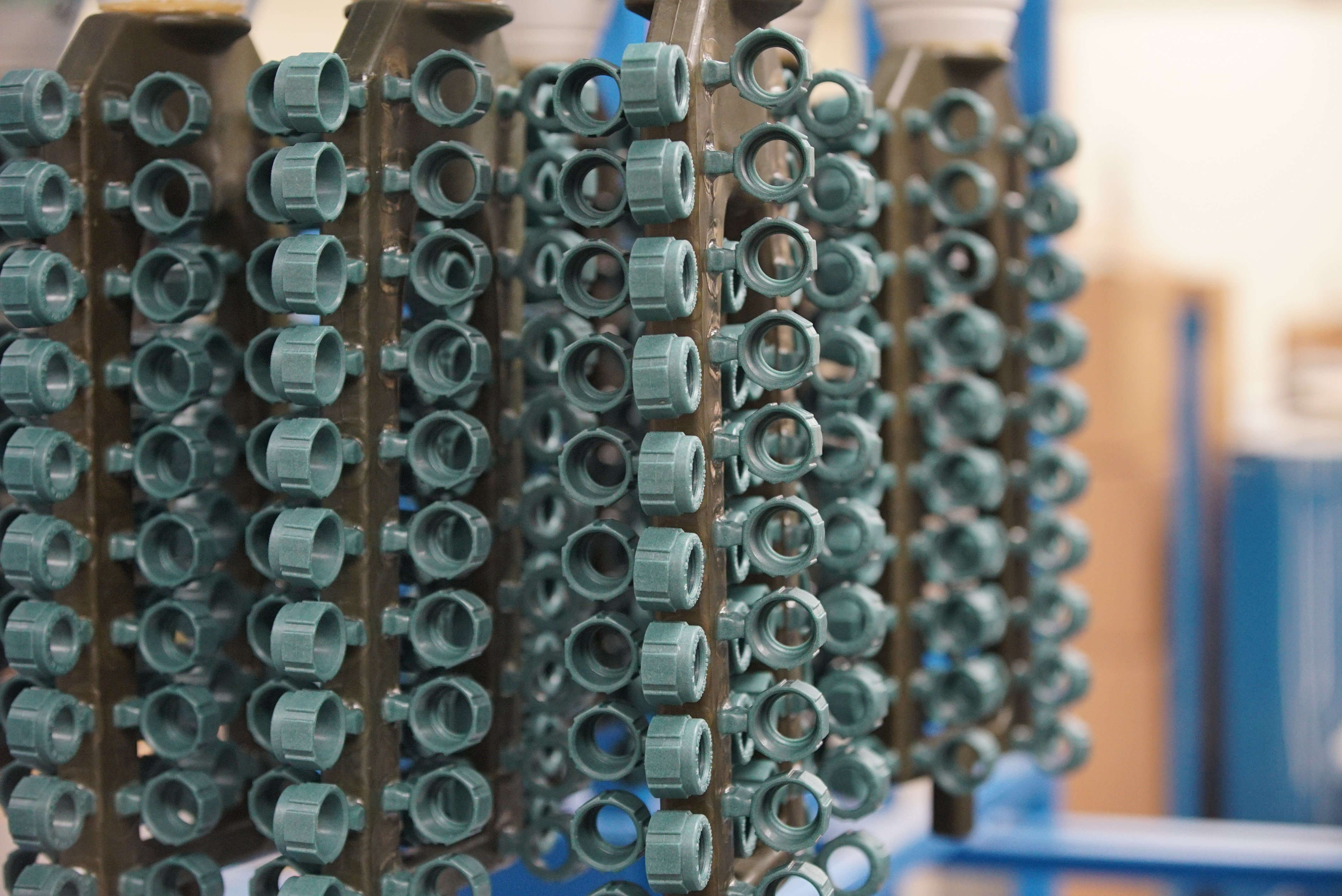

One of the keys to a quality plastic injection molded part is an accurate mold – one that produces consistent pieces time and time again. So how is that accomplished? First, if you are not familiar with the components of an injection mold and how they work, take a look at this blog post: Components of An Injection Mold to brush up on the basics..

Thermoset vs. Thermoplastic: Which is Right for My Product?

When it comes to choosing the right plastic for your product, there are an overwhelming number of options. The first thing you need to narrow down is this: thermoset or thermoplastic? Your decision will be largely based on your product's specifications and final application. Let's examine the differences between the two, the pros and cons of each,...

Setting up an engineering lab may feel like a mammoth task, but the most important thing to keep in mind is that safety should always be your top priority. Protect your employees and keep your engineering lab running efficiently with the following 10 lab safety tips.

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. The acronym DFMA (Design for Manufacturing and Assembly) is sometimes used interchangeably with DFM.

The product design and development process is a fascinating one, marrying creativity with the disciplines of math, science, engineering and marketing. Transforming an idea into a marketable product doesn’t just happen.

You don't need to be part of the manufacturing industry long to learn it has it's own native language with no shortage of acronyms. BOM, CBOM, EBOM, MBOM -- it can get confusing very quickly, but we've got you covered with this dictionary of the most commonly heard terms to help you navigate your way through the product development process.

Casting -- one of the oldest known manufacturing techniques -- is a process in which liquid material (e.g. molten metal) is poured into a mold cavity and hardened. After removing the piece from the mold, various finishing treatments can be applied to create a dazzling final product. This process is used primarily to manufacture complex solid and...

Practical Ways Engineering Support Benefits Product Development

When considering the value of engineering support as you go through the process of product development, there’s a great saying to keep in mind:

Experience is a great teacher, especially someone else’s experience.

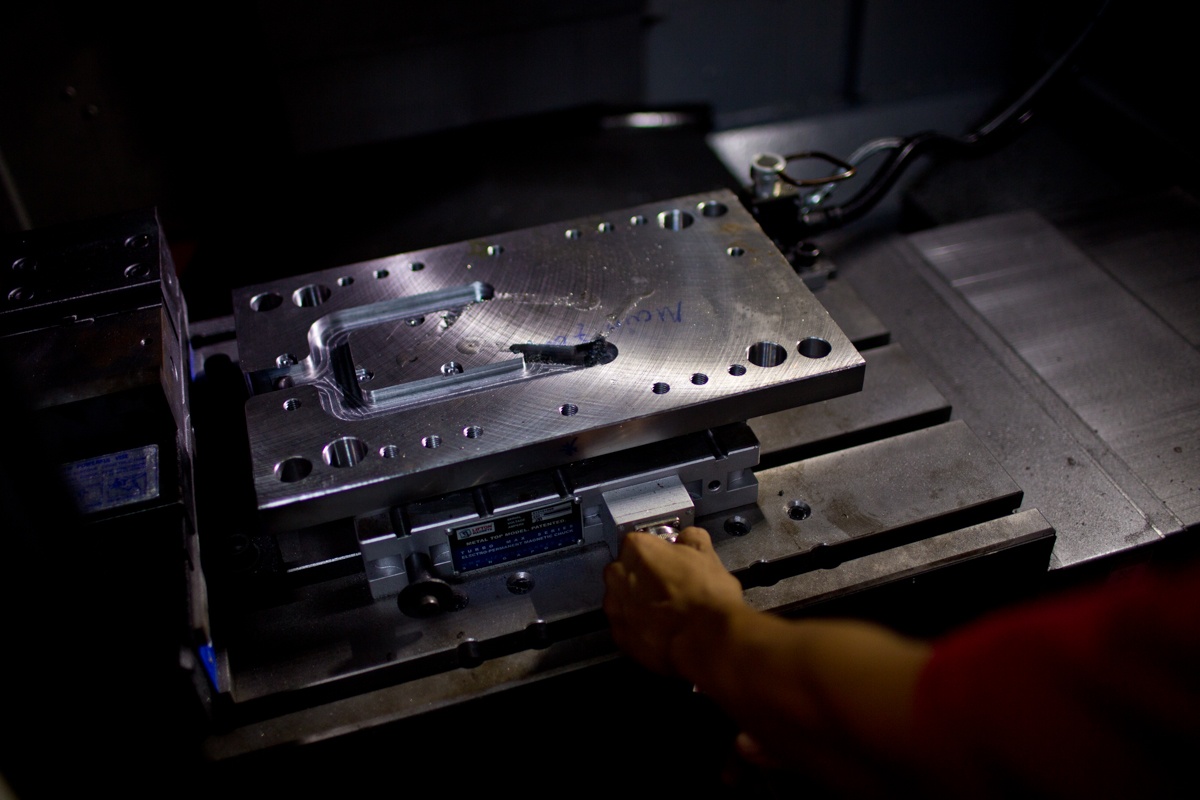

Toolmaking is one of the most critical and expensive items on the manufacturing to-do list. And because your tool is the basis of your part or product, every decision you make about how your tool is made is, by default, a decision about the quality of your product.

Anything that significant is worth understanding in detail, but how much do you...

Here’s the scenario: You have a part that you’ve been making and selling but you’ve decided to put it out to quote. You send your drawings package and samples of the part to a contract manufacturer that has a reputation for providing quality engineering support. In reviewing the drawings, the project engineer picks up on a small but significant...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)