You’ve submitted your design, you’ve seen your prototype and… there’s something not quite right. Maybe a curve is deeper than expected, there’s a ridge or dimple where there shouldn’t be. Perhaps it just doesn’t feel the way you expected it to. But it’s a simple fix, right?

How Small Design Changes Can Affect Product Development Pricing

The Most Common Product Design Mistakes and How to Avoid Them

Designing a new product is as easy as having a great idea, right? Not right. There is a lot that goes into designing, developing, manufacturing, marketing and selling a new product. Millions of products have failed, and chances are that all of them had at least one of the below mistakes in common. Save your product – and business – from an...

If you were going to make a cake, you would certainly want to start with a recipe. The recipe provides instruction on what ingredients to use, and in what quantities. In addition, a good recipe will provide instruction on how to prepare the ingredients – the order to mix them in, special instructions such as freezing or thawing ahead of time, oven...

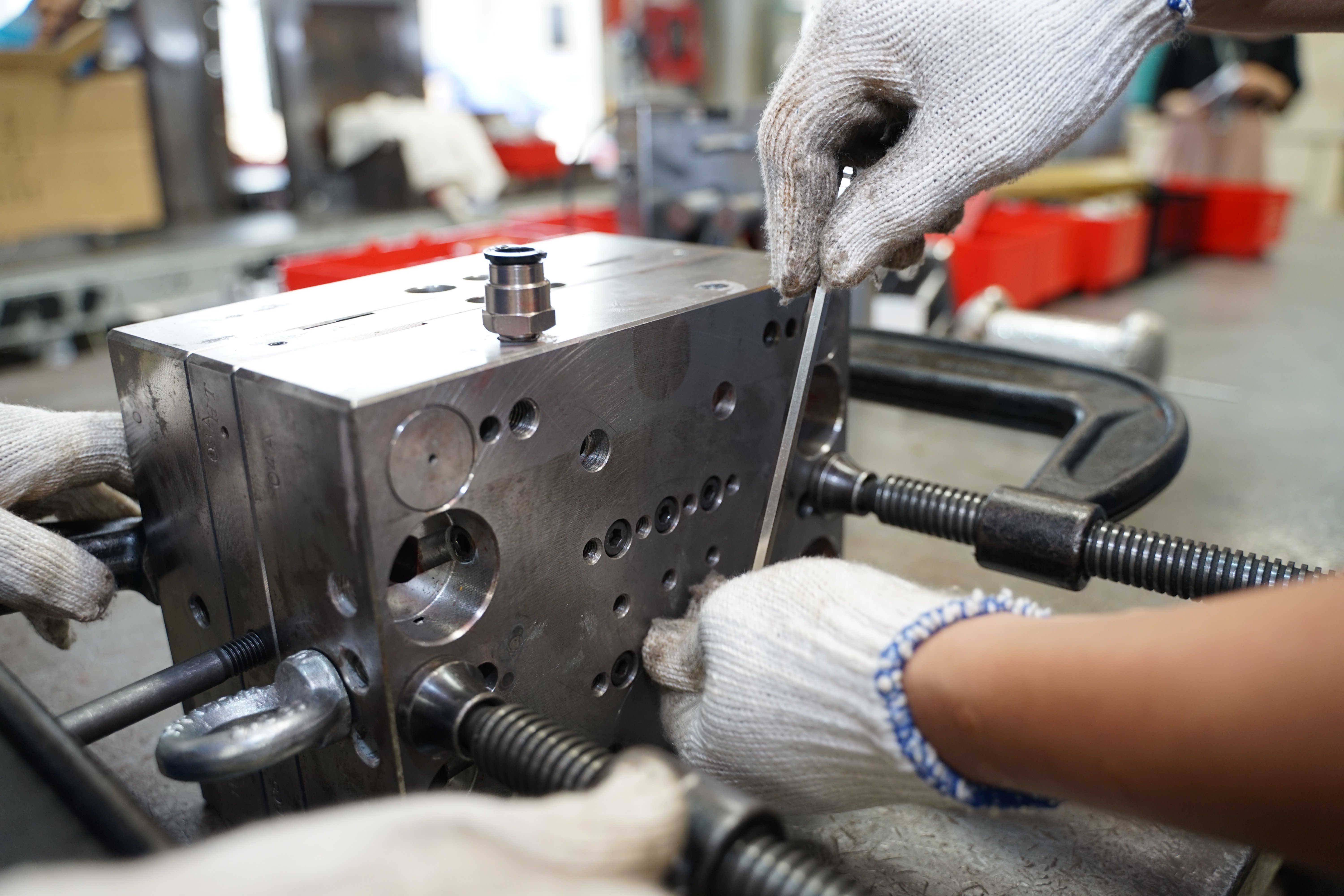

After spending months or perhaps years of blood, sweat and tears on the development of your product, the wait between achieving your Production CAD Release milestone and that holiday-like buzz of unwrapping your first off-tool parts can be excruciating. Despite today's same-day delivery mindset, creating a tool still follows the same general...

If death and taxes are two guarantees in life, time and money are the two constants when taking an idea from the prototype stage through new product introduction (NPI) into commercial launch.

But have you ever wondered what it looks like to take a product from prototype to production? It's a complex process that combines creativity and procedures....

Reducing costs is an ongoing task for every company, but what if I told you that you could save money without having to change a single millimeter of your product?

You’d probably be thrilled.

If you thought the new product development process was going to be a walk in the park, you might need to take a look at a survey conducted by Gartner in 2019. The survey questioned CEOs about the success of new product introduction, and the numbers were sobering.

The product design and development process is a fascinating one, marrying creativity with the disciplines of math, science, engineering and marketing. Transforming an idea into a marketable product doesn’t just happen.

Practical Ways Engineering Support Benefits Product Development

When considering the value of engineering support as you go through the process of product development, there’s a great saying to keep in mind:

Experience is a great teacher, especially someone else’s experience.

When you work with engineers prepare yourself for a heaping helping of acronym soup! You’ll hear it all: PCB, PCBA, DFM, FMEA, PO, IP and of course the BOM, which stands for Bill of Materials. And while all those other acronyms are highly important to the product development process, it’s the BOM that gets you on your way.

.jpg)

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)