Why Conformal Coat?

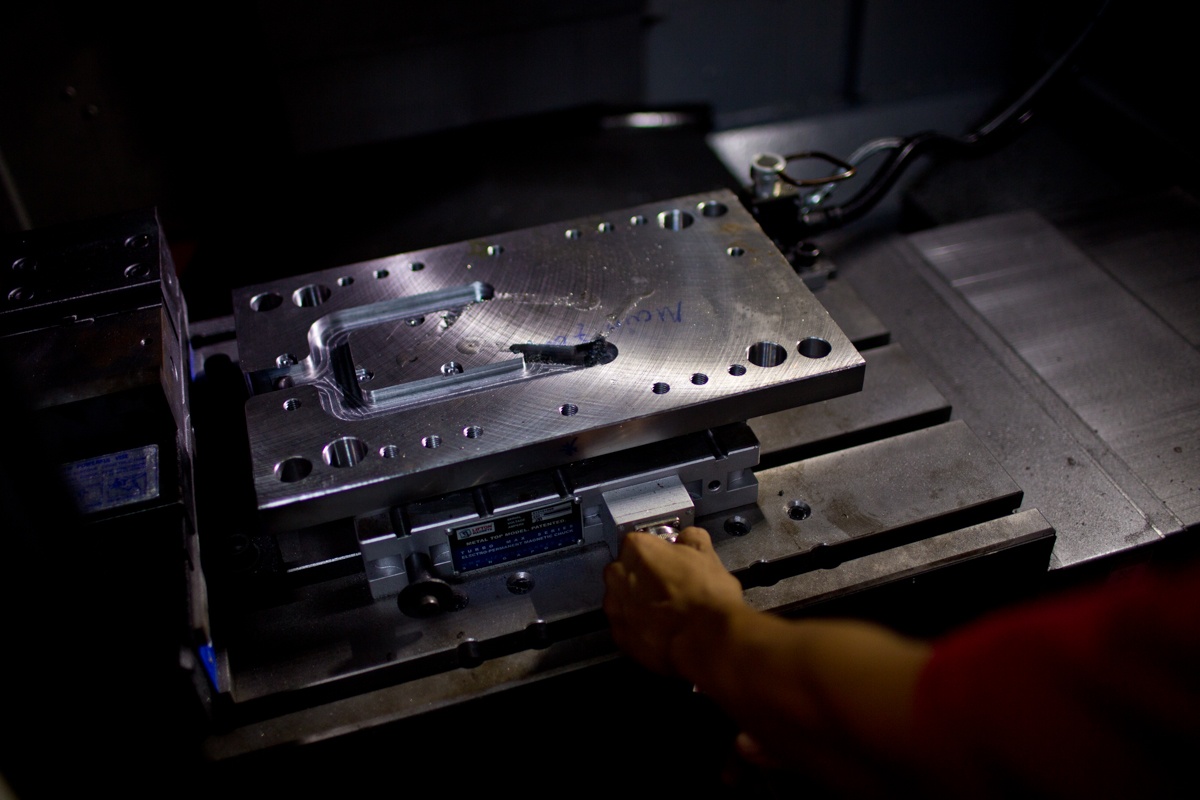

The function of circuit assemblies can deteriorate due to external factors such as moisture, salt spray, chemicals, and temperature extremes. Conformal coatings can be used in a wide range of environments to protect against damaging effects like corrosion, mold growth, and electrical failures caused by outside agents. This...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)