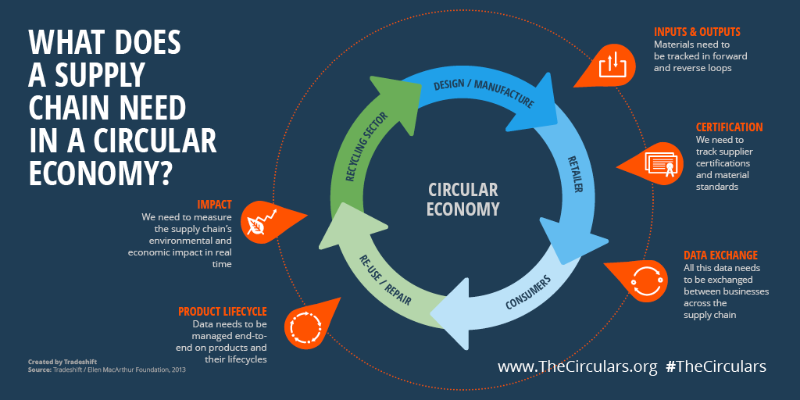

Supply chain visibility (SCV) is the ability of parts, components or products in transit to be tracked from the manufacturer to their final destination. According to TechTarget, the primary objective of SCV is to improve the availability of data to stakeholders and customers alike, ultimately strengthening and improving the supply chain.

Because n...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)