In this day and age, it's simply not enough to state a claim of corporate social responsibility. We need to enact change. A company concerned with sustaining its marketplace must take action, and one practical jumping off point is supply chain analysis. Aim to transform your supply chain from a linear (take-make-dispose) model to a circular (no-waste) one, contributing to what's known as the circular economy – one focused on waste elimination and sustainability.

What is a Circular Supply Chain?

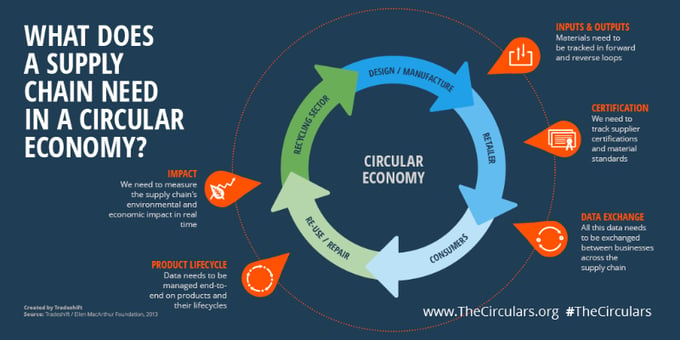

A circular supply chain is one that keeps resources in use as long as possible. One that reduces waste at every stage, from design to distribution and beyond. One that is creative and mindful of the bigger picture. Think of it as a more widespread and impactful relative of lean manufacturing. The graphic below, courtesy of Tradeshift, might help you visualize the circular supply chain. It's important to note that re-use/repair comes before recycling in this flow. Because recycling can be an energy-intensive process, identifying re-use opportunities first can save a sizable amount of energy in the long run.

Click the image to view larger.

Image via TheCirculars.org

Image via TheCirculars.org

Why Does a Circular Supply Chain Matter?

If corporations fail to act soon, we'll face major consequences worldwide, from growing carbon footprints to further ozone depletion and lost dollars as a result of widespread waste. The situation calls for mass overhauls and industry-wide reform. However, it's not all gloom and doom. Some companies are taking the lead and tackling the issue head-on.

One company making strides is Netherlands-based Dutch aWEARness, which has created its own barcode-enabled, track-and-trace system to follow clothing through its entire lifecycle. Once a consumer has finished using an article of clothing, s/he returns it to the company, where the eco-friendly materials are repurposed, drastically reducing waste. Dutch aWEARness makes corporate uniforms as well as streetwear.

4 Steps to Building Your Circular Supply Chain

1. Shift Your Thinking

- All team members must get in the right mindet

- Consider ideas you never considered before, and stop saying "we've never done it that way."

2. Redesign For Sustainability

- Take a look at the full product lifecycle and identify opportunities to improve sustainability at each stage.

- Identify new competitive advantages in design

In addition to establishing a product recycling program and working with natural materials, companies can utilize sustainable energy sources during the manufacturing process. Using renewable energy, including hydrogen, solar, wind and biomass power, is one approach corporations and nations are taking to address this crisis.

3. Collaborate

- Think as part of a network, not as an individual

- Work with others who have shared goals and work to increase efficiencies together and for mutual benefit

- Be an example for your industry and strive to enact change industry-wide and beyond

4. Regenerate Materials

- Maintain, reuse and refurbish or recycle instead of scrapping

- Turn outputs into inputs by closing the loop and utilizing reverse logistics

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)