In modern supply chains, where efficiency and real-time data are vital, the integration of cutting-edge technologies has become imperative. One example that is reshaping the way companies manage their inventory is the merging of printed electronics with supply chain management. This technology holds the potential to transform traditional packaging...

East West Manufacturing

Recent Posts

How Smart Packaging is Transforming Real Time Inventory Management

How Strong Supplier Relationships Add to Your Bottom Line

Studies by Planning Perspectives, Inc. (PPI), determined a causal link between a company’s profitability and the quality of the relationships it has with its suppliers. Dr. John W. Henke, Jr., president and CEO of PPI, specializes in studying OEM buyer/supplier relationships in the automotive and 17 other industries. His company publishes an...

When it comes to printed electronics for medical and wearable products, making the right choice for your manufacturing partner is critical. These specialized devices demand precision, compliance with stringent regulations, and a commitment to quality. In our experience, there are several key considerations and strategies that will help when it...

The electric vehicle (EV) industry is experiencing remarkable growth, and as more electric cars hit the roads, the need for a reliable and efficient charging infrastructure becomes increasingly evident. While the spotlight often shines on the advancements in EV battery technology and vehicle design, the supporting infrastructure plays a pivotal...

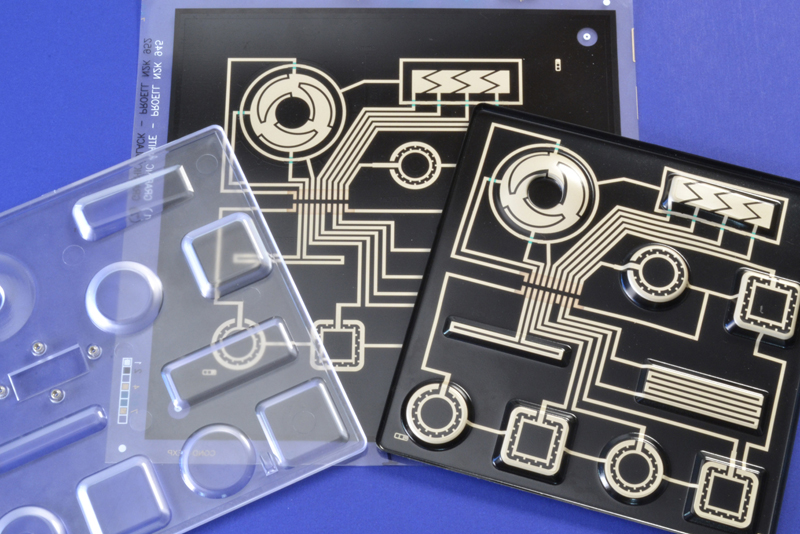

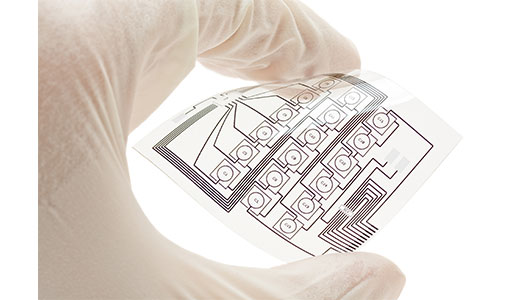

If you are looking for a way to create smart surfaces and human-machine interfaces that can integrate decorative graphics, lighting, touch controls, sensors, antennas, and other features into plastic parts, you may want to consider in-mold electronics (IME) as part of your product design plan.

What Affects The Cost of Printed Electronics Manufacturing

The cost of manufacturing printed electronics can vary significantly based on a variety of factors, including the complexity of the design, the materials used, the production volume, and the level of quality control required. As a result, there is no fixed cost associated with manufacturing printed electronics. Instead, the cost is determined on a...

Challenges When Scaling Up Printed Electronics Manufacturing: Part 2

Material compatibility and sourcing becomes increasingly complex when scaling up printed electronics production. Because materials (substrates, conductive inks, dielectrics, hydrogels) are the building blocks of printed electronic components, ensuring a consistent, reliable supply of high-quality materials is essential for successful large-scale...

Challenges When Scaling Up Printed Electronics Manufacturing: Part 1

Part 1: Inconsistent Printing Quality

As the demand for printed electronics continues to grow, manufacturers face a significant challenge—scaling up production efficiently while maintaining product quality and cost-effectiveness. To do so successfully, you must first understand the most common challenges companies experience. Then, we can walk...

Overseas manufacturing is challenging enough, and now more than ever we are seeing disruptions at nearly every stage of the process from availability of raw materials to logistical nightmares and port congestion. Not to mention the typical challenges related to distance, time zones, language barrier, cultural differences. And if forecasting falls...

What are Conductive Inks?

When we really get down the meat of it, conductive inks are simply printed products capable of conducting electricity by infusing silver flakes and other conductive metallic materials into the ink itself. While most metal materials maintain a solid state at normal temperatures, infusing liquid inks with flaked or powdered...

.png)

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)