Want a simple way to potentially save on production costs?

Take a look at your tolerances.

Ask yourself these questions:

- What is the part's function?

- Can I justify this tight tolerance or does it fall into the non-critical category?

- Is it critical for fit or function?

- What process is being used? (Sometimes tight machining tolerances are being applied when casting tolerances are more appropriate.)

- Is this tolerance passed down from a previous-generation or legacy product? Is it still appropriate?

Your contract manufacturer (CM) can identify unnecessarily tight tolerances and suggest more appropriate ranges.

Design Tolerance Standards

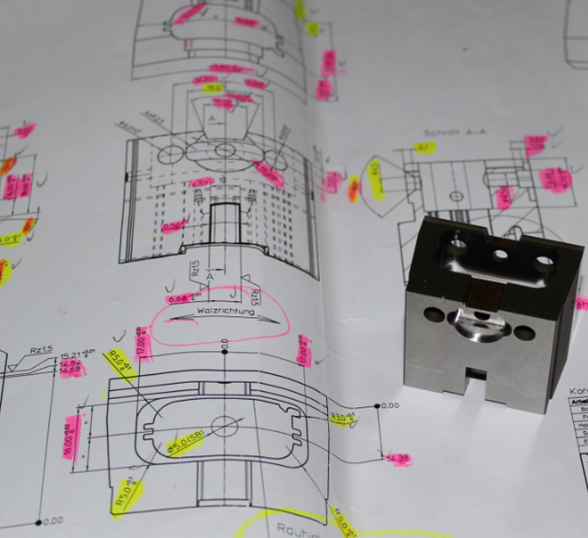

Tolerances are usually specified on customer drawings. If not, the CM will recommend a class for the item and a set of standards to follow. The two standards we reference for mechanical tolerances are ASME Y14.5 and ISO1101.

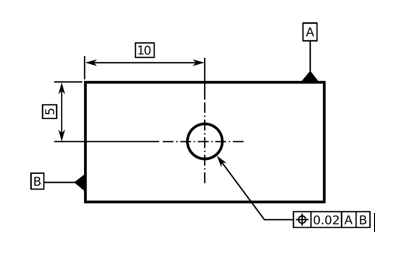

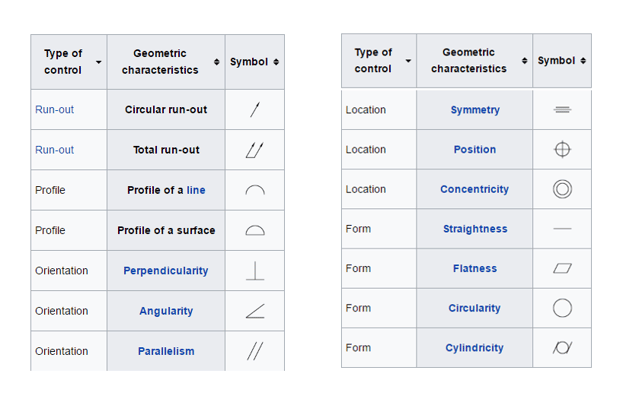

ASME Y14.5 uses a system called Geometric Dimensioning and Tolerancing (GD&T) to help specify form, location, orientation and other descriptors to a feature on a print. The features are called out relative to Datums – shown as letters in blocks.

For electrical tolerances we turn to IPC (an international association for electronics companies):

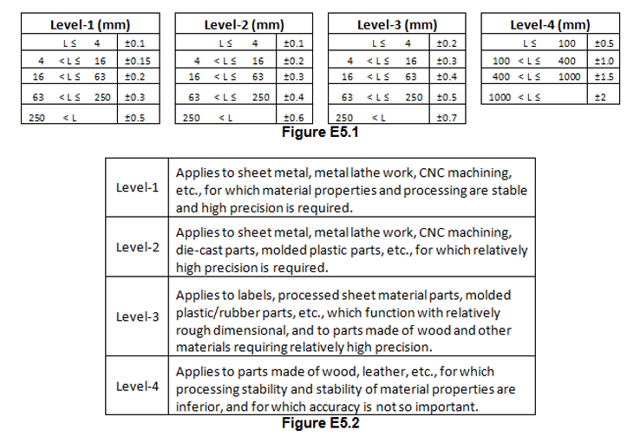

Material and Manufacturing Tolerance Standards

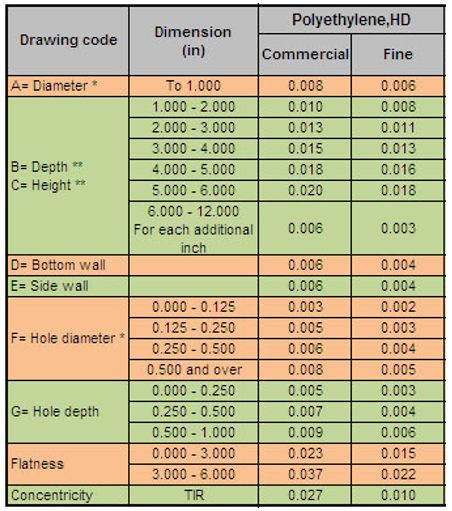

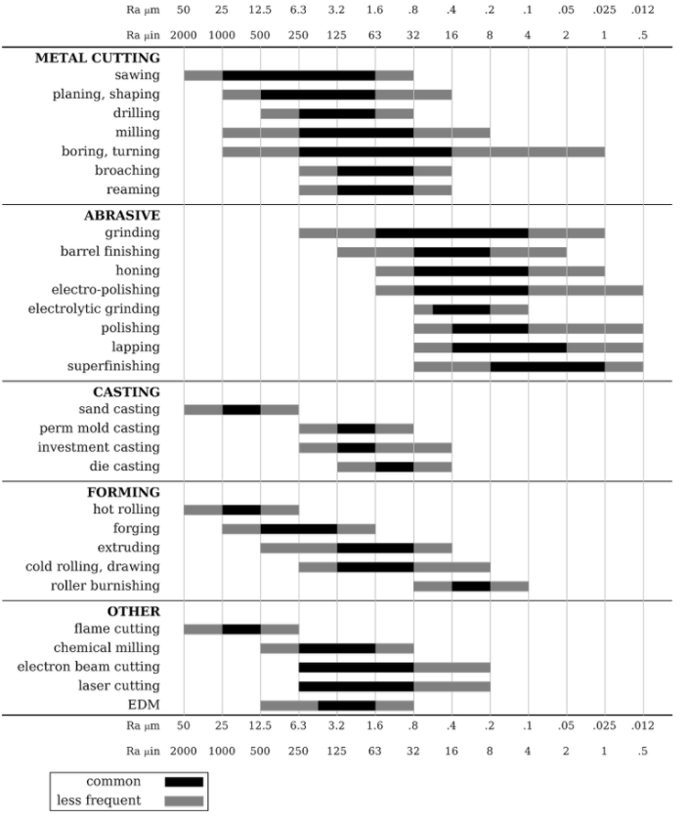

Design tolerance standards allow engineers to specify how to tolerance a part. Material and manufacturing processes allow engineers to specify how much tolerance they can use for a feature. The final application of the component should dictate the tolerance values required. All standard manufacturing processes and materials have standards in place to control the requirements necessary to reach specified criteria. For example, the charts below show the tolerance range for injected molded, high density polyethelene and the surface finish capabilities for metal cutting processes.

Tolerance Range: Injection Molded High Density Polyethlene

Surface Finish Capabilities for Various Metal Cutting Processes

(Chart: Materials and Processes in Manufacturing)

Four Ways Tighter Tolerances are Costing You

- More expensive tooling - The tighter the tolerance the more it costs. Higher grade materials allow for more precision, but cost more to make.

- Additional Processes - Tighter tolerances often require additional operations and tools/machines — adding cost. An example is surface finish required for metal; grinding, honing, and polishing are expensive secondary operations, and should only be used if absolutely required.

- More expensive testing - Close inspection is required for parts with critical tolerances. This means additional time and labor, whether the testing is manual or automated. Sometimes tight tolerances require inspection of each component, rejecting parts that are out of spec — even those that could be used if tolerances were more reasonable. Sorting and high reject rates show up in high component prices.

- Precision equipment and manufacturing - Using precision equipment and manufacturing processes to meet tight tolerances means one of three things that will cost you more money.

- Your supplier will charge a premium for using their niche, precision machines.

- They will invest in more sophisticated machinery and processes if they don't have them in place already.

- Certain processes will be outsourced to another supplier with these capabilities.

Look: It doesn't cost you anything to look over your design to see if there are places where tolerances can be loosened. And it might just save you some money. Maybe you'll find something and maybe you won't. The key is to find that delicate balance between tolerances that are too tight and too loose. Think critically and identify areas where tight tolerances are absolutely crucial, and go from there.

Read more about product design and development:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)