Nothing steals the joy out of submitting an RFQ faster than realizing you’ll be waiting weeks longer than promised to get the quote back, or worse, you get the quote quickly, but it is wildly inaccurate.

While you cannot control with what speed or level of accuracy a manufacturer completes their quotes, there are some steps you can take when preparing your bill of materials (BOM) to reduce unnecessary back-and-forth emails that will delay your quote any further.

BILL OF MATERIAL 101: WHAT IS IT?

Most of us have that one family recipe Grandma finally wrote down, but even when followed perfectly, it’s never quite as good. Well, that’s because Grandma failed to include a couple of key ingredients. Just like her famous bolognese, the BOM is your recipe, containing all the information necessary to make your product. The more detailed the BOM is, the better the outcome. While you’re likely already including the minimum details necessary such as part number, name, quantity, cost and unit of measure; there are a few items you may not be incorporating that you should consider adding to give your manufacturer the best chance of getting it right the first time.

REVISION DATE OR NUMBER

We’ll start with the easiest one. Bills of material often go through many iterations. Requirements change, designs are adjusted, and your manufacturer needs to know which document you’ve sent is the most up-to-date version. The simplest way to accomplish this is by indicating in the file name which version this BOM is, or the date of the last revision. It may seem like a basic task, but this will ensure the correct document is being referenced throughout the organization.

DON’T FORGET THE PCB

This is also going to seem elementary, so we’ll keep it short. If you’re quoting a PCBA, list the raw board in your BOM. You’d be surprised how often this detail is left out.

LIST OF ALTERNATE PARTS

These days, finding the exact parts you need in the quantity required feels like the wild west. We’ve been writing about the component shortage for years prior to the pandemic, but COVID-19 took the scarcity of parts from bad to worse. If there is one thing buyers have learned from this, it is the value of flexibility. The probability that at least one required part will be unavailable is high, so listing approved alternates on your BOM will save you and your manufacturer a lot of time.

PRE-OWNED TOOLING INFORMATION

Maybe you are switching from one manufacturer to another and have already invested in tooling. These are expensive, and it would only make sense to want to re-use what already exists. Communicate to your supplier in advance that you’d like to utilize your pre-existing tools. If possible, share the contact information for the representative, and your new manufacturer will get in touch directly.

NOTICE OF SECURED PRICING

If you already have inventory of any parts for the project being quoted and would like to consign them to your manufacturer, or maybe you have secured pricing for a part directly from the source, this communication is best made before the team begins the quoting process. Consider submitting a letter of authorization (LOA), allowing your supply chain partner the right to buy specific components at a previously agreed upon price - often lower than the manufacturer could buy on their own. Failing to share this information preemptively will result in an inaccurate quote and greatly lengthen the time it takes to receive your final quote package.

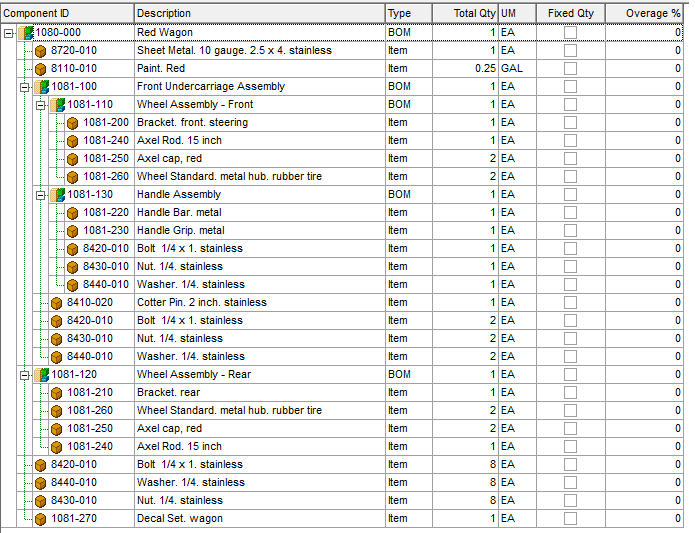

UTILIZE INDENTED BOMS

When the project contains subassemblies, using an indented (or multi-level) BOM is crucial. This style of BOM means the parent item will be placed furthest to the left, while each level indented underneath will map out the components that are required to create the parent item above it.

While most people understand this concept, customers will often forget to use this practice for program parts on a PCBA as well. Program parts will typically contain the blank, as well as the actual software. In this scenario, the program part should be a level 1, while the blank and the software are both level 2.

Not only will proper use of a multi-level BOM create a smoother quoting period, but it will also prevent errors and loss of time in the manufacturing process.

QUANTITY TO ZERO FOR ANY PARTS NOT TO BE INSTALLED

There may be times when your BOM lists parts that, for a variety of reasons, you do not want installed. While it is helpful to include a comment such as “Do not populate” in the notes section of your bill of material, that isn’t enough. Remember most manufacturers now are using automated quoting software that will take its information directly from the quantity column of your spreadsheet. Any parts you do not wish to have quoted will need to have a quantity of “0” to yield an accurate result. Failing to make this adjustment means the quoting specialist will need to spend time manually adjusting your document which is not something they typically like to manipulate for risk of unintentional errors.

An accurate BOM is critical for successful quoting, and ultimately a smooth manufacturing experience. Incomplete BOMs lead to confusion at every level of the organization from quoting to engineering and final production. It can lead to an increased risk of error, longer lead times and unnecessary stress, especially during times of a shaky global supply chain. Incorporating the tips above will help ensure your quoting experience is positive and seamless.

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)