In modern supply chains, where efficiency and real-time data are vital, the integration of cutting-edge technologies has become imperative. One example that is reshaping the way companies manage their inventory is the merging of printed electronics with supply chain management. This technology holds the potential to transform traditional packaging into intelligent, data-driven solutions, creating a powerful tool for enhanced inventory and logistics monitoring.

The Power of Printed Electronics:

As a refresher, printed electronics involve the fabrication of electronic circuits and components using printing technologies, such as inkjet or screen printing, on flexible substrates like paper or plastic. This capability to print electronics functionality onto a variety of surfaces opens new possibilities for the development of smart packaging that goes beyond the conventional role of protecting goods during transit.

Smart Packaging: A Game-Changer in Supply Chain Management:

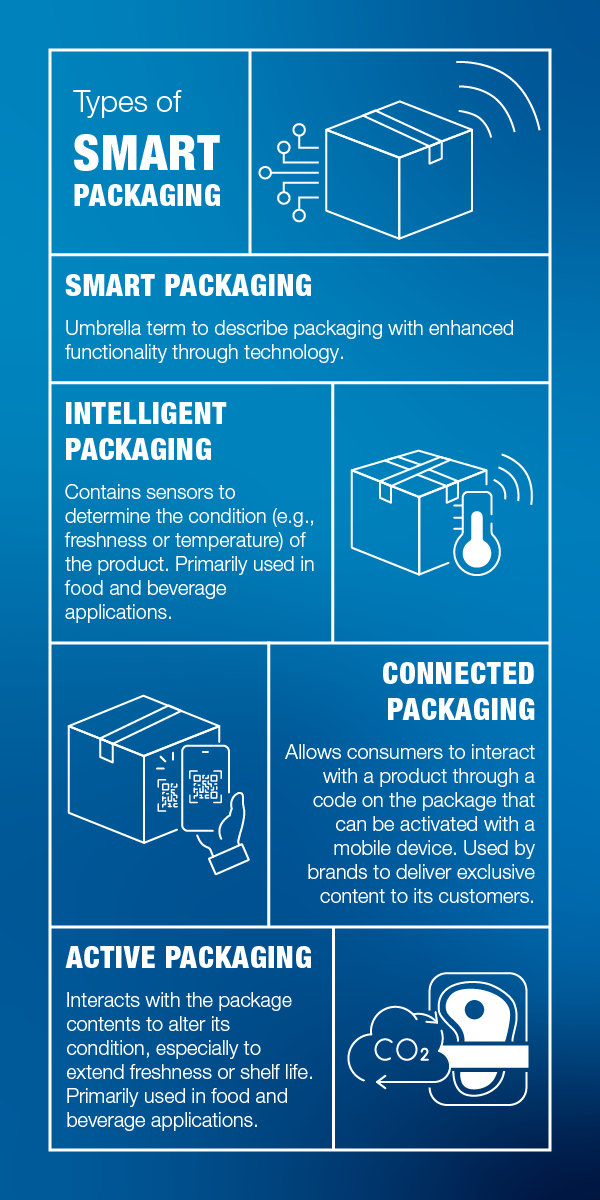

Traditional packaging has long been limited to its primary functions of containment and protection. However, with the integration of printed electronics, packaging can now become an intelligent part of the supply chain. Smart packaging, sometimes also known as intelligent packaging, contains sensors, RFID tags, and other electronic components directly onto or into packaging materials. These can determine the condition (e.g., freshness or temperature) of the product. It is often used in food and beverage applications.

The advantages of smart packaging are significant. They enable real-time monitoring of various parameters such as temperature, humidity, and even the integrity of the package itself. This level of visibility into the conditions of the transported goods ensures that any deviations from optimal conditions can be quickly identified and addressed, preventing potential damage or spoilage.

Real-time Inventory Monitoring

One of the most promising applications of printed electronics in supply chain management is the implementation of real-time inventory monitoring. Traditional inventory management systems often suffer from delays and inaccuracies, leading to inefficiencies and increased operational costs. Printed electronics offer a solution by providing a continuous stream of data regarding the location and status of each item in the inventory.

RFID (Radio-Frequency Identification) tags, integrated into packaging through printed electronics, play a pivotal role here. These tags can communicate wirelessly with RFID readers, updating the central inventory management system instantaneously. This means a more accurate and responsive understanding of stock levels, reducing the risk of stockouts or overstock situations.

Benefits of Printed Electronics in Supply Chain:

- Enhanced Visibility: Printed electronics enable real-time tracking and monitoring of goods throughout the supply chain. This enhanced visibility is crucial for supply chain experts to make informed decisions and optimize operations.

- Reduced Costs: The accuracy and efficiency provided by real-time inventory monitoring contributes to cost reductions. Companies can minimize carrying costs, prevent stockouts, and streamline their logistics processes.

- Improved Product Quality: Smart packaging equipped with printed electronics allows for monitoring environmental conditions, ensuring that products are transported and stored under optimal conditions. This results in higher product quality and customer satisfaction.

- Faster Response to Issues: With real-time data on the condition and location of goods, supply chain experts can respond swiftly to potential issues, such as delays or deviations in transportation, preventing disruptions and minimizing the impact on the supply chain.

Challenges and Future Prospects

While the potential benefits of printed electronics in supply chain management are vast, there are challenges that need to be addressed. These include the upfront costs of implementing such technologies, the need for standardized communication protocols, and concerns related to data security and privacy.

Looking ahead, ongoing research and development in printed electronics are likely to address these challenges and further enhance the capabilities of smart packaging. The integration of artificial intelligence and machine learning algorithms could also play a role in optimizing inventory management processes, making them more predictive and proactive.

According to ID Tech Ex, the smart packaging industry is expected to be valued at $2.6 billion in 2033, reflecting a CAGR of 15.4%. This growth is lead heavily by the pharmaceutical, ecommerce, and the food and beverage sectors.

Printed electronics for smart packaging and real-time inventory monitoring represent a groundbreaking advancement in the field of supply chain management. For manufacturers and supply chain professionals, embracing this technology offers the potential to completely transform their approach to inventory control, improving efficiency, reducing costs, and ensuring the highest quality of delivered goods. As technology continues to evolve, companies that adopt printed electronics in their supply chains will likely gain a competitive edge in an increasingly complex and fast-paced global market.

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)