Everything we know is being disrupted. The way we buy groceries or read the newspaper (what’s a newspaper?), the way we travel and communicate. Fueled by breakneck advances in technology, disruption has made its way into every industry, including manufacturing.

In Germany, a nation on the forefront of the Industrial Internet of Things (IIoT), it’s called "Industrie 4.0," part of the government’s initiative to revolutionize manufacturing and production. These smart factories lean heavily on technology to connect things (infrastructure, operations, robots) with people in a host of ways (computers, mobile devices, wearables).

Of course, the idea behind this revolution isn’t implementing technology for technology’s sake. The result should be creation of efficiencies across divisions and platforms; developing a nimble manufacturing organization capable of making intelligent, data-driven and timely course corrections.

Better data = Better decisions = Better outcomes

Deloitte University Press released an excellent report, 'The Smart Factory: Responsive, adaptive, connected manufacturing,' as part of a series on Industry 4.0, digital manufacturing enterprises and digital supply networks. We’ll share some of the highlights in this post but do yourself a favor and download it. Share it with your team and your employees. It’s good reference material and provides the basis for the “whys” behind smart technology in manufacturing and many of the changes you’ll undoubtedly implement in the next few years.

Benefits of Creating a Smart Factory

Asset efficiency

Smart technology collects massive amounts of data on processes (both human and machine) which can be analyzed for trends or inefficiencies. In other words, you learn what works and what doesn’t. As the report states, asset efficiency translates into:

- Lower asset downtime

- Optimized capacity

- Reduced changeover time

Quality

The smart factory uses technology that can spot defects and defect trends quickly, and identify the weak link — human, machine or environmental. This would result in faster identification of items requiring rework and bring about lower scrap rates, overall. The faster your team can identify and fix the problem, the better quality over the product lifecycle.

Lower Cost

Over time, smart factory processes will lead to more cost-effective processes — in inventory and hiring/staffing, for example — and a higher degree of predictability. “A better-quality process could also mean an integrated view of the supply network with rapid, no-latency responses to sourcing needs — thus lowering costs further,” the report reads. “And because a better-quality process also may mean a better-quality product, it could also mean lowered warranty and maintenance costs.”

According to the report, operational efficiencies of a smart factory can lower a company’s environmental footprint while increasing environmental sustainability. Process autonomy often means fewer opportunities for human error resulting in injury. Human workers would still be needed with opportunities for higher critical-thinking, but their jobs would be less repetitive or potentially injurious (repetitive motion syndrome).

Effect of the Smart Factory on Manufacturing Processes

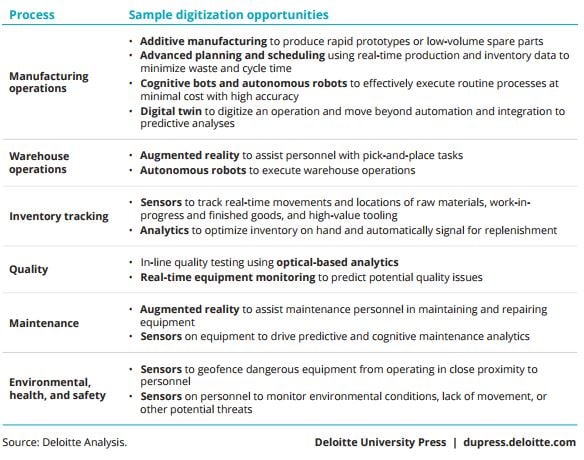

The chart below shows some of the ways using digital technology can be embedded in a smart factory:

How to Begin: Considerations and First Steps

Every factory is unique, but the Deloitte reports says there are five major points you will have to consider when you’re configuring your smart factory: data, technology, process, people and security. All these factors are equally important, but may be prioritized differently from one company to the next.

- Data - Data runs the show. You’ll need to invest in scalable data solutions that will create data sets required to track, analyze and predict. Don’t forget: You’ll need to store the data, too.

- Technology - Your factory and everything in it will need to be connected in order to communicate with each other and the central control system. This can involve implementation of digital and physical technology such as artificial intelligence (AI), high-performance computing and analytics.

- Process - Because digital technologies break down the four walls of the factory and create high level interactions between suppliers, customers and other factories, new collaborations may form that require companies to rethink decision-making processes to better reflect the relationships.

- People - There will always be a need for people, even in the smart factory, but new roles - perhaps cross-functional roles - will emerge from the new technology. Communication about changes is essential to a smooth transition to smart factory technology.

- Cybersecurity - The extensive connections inherent in a smart factory create a larger cybersecurity risk with greater potential for impact in the event of an attack. Cybersecurity must be an ongoing high priority for any company converting to smart factory operations.

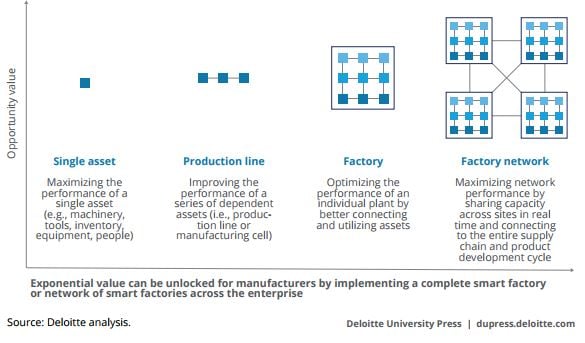

The best way for a company to take the smart factory plunge is to “think BIG, start small and scale fast.” In other words, be aspirational in your vision, realistic in your implementation but move quickly. Think strategically and stay focused on your objective. “Value creation can begin with and scale from a single asset, and use an agile approach to iterate and grow,” says the Deloitte report.

Maybe you think your company is too small to even consider smart factory solutions. I would counter that argument with this one: If your company is small, it’s easier to implement smart factory technology. Maybe you think your company is doing fine, you have all the technology you want. That’s fine, but what about your customers? What about your suppliers? Other companies are already implementing smart factory technology, with many more on the way. Your company can’t afford to be left behind.

Consider the findings from a report by Capgemini, ‘Smart Factories: How can manufacturers realize the potential of the digital revolution.’ Top three takeaways from their global research:

- Smart factories could add $500 billion to $1.5 trillion in value added to the global economy in five years

- Manufacturers predict overall efficiency to grow annually over the next five years at 7 times the rate of growth since 1990

- We estimate that smart factories can nearly double operating profit and margin for an average automotive OEM manufacturer

Both the Deloitte and Capgemini reports paint a rosy picture of smart factory initiatives, but everyone knows it won’t be an easy or seamless transition. Arming yourself with information now, positions your company to succeed in this exciting new phase of manufacturing.

Read more about how technology is affecting manufacturing and supply chain:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)