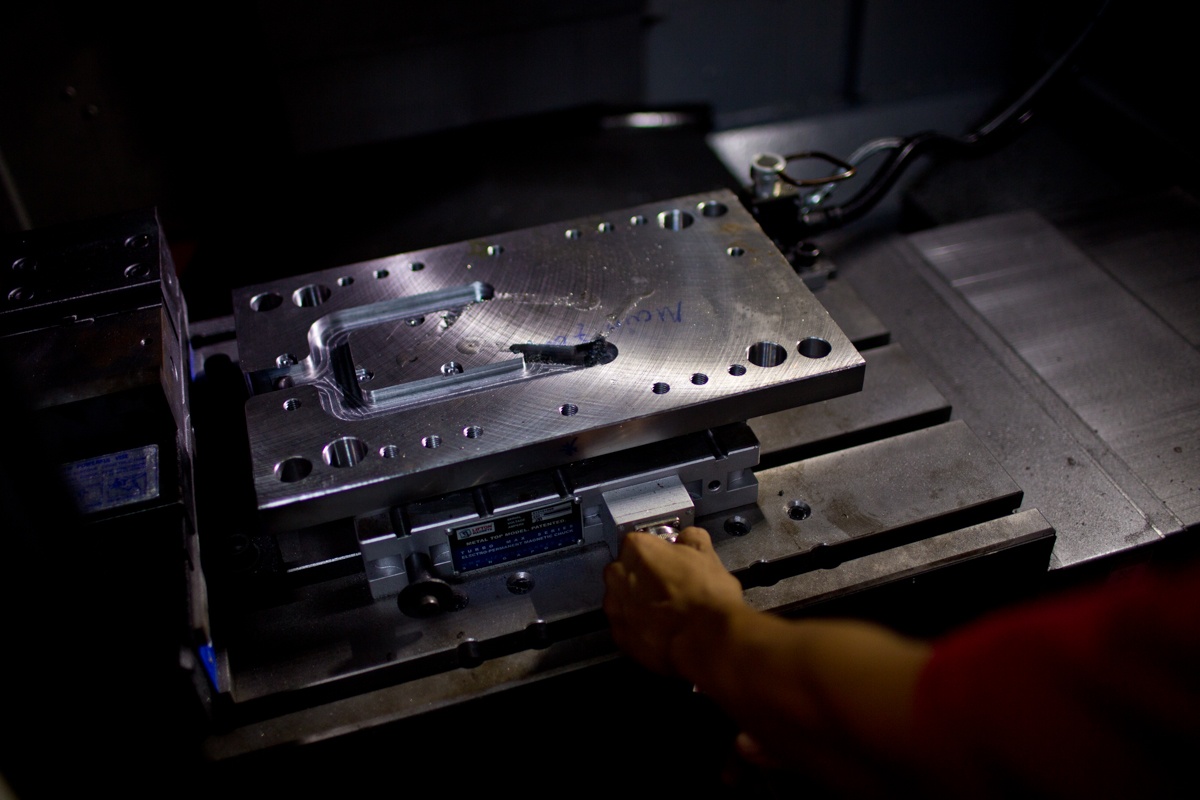

One of the keys to a quality plastic injection molded part is an accurate mold – one that produces consistent pieces time and time again. So how is that accomplished? First, if you are not familiar with the components of an injection mold and how they work, take a look at this blog post: Components of An Injection Mold to brush up on the basics..

After spending months or perhaps years of blood, sweat and tears on the development of your product, the wait between achieving your Production CAD Release milestone and that holiday-like buzz of unwrapping your first off-tool parts can be excruciating. Despite today's same-day delivery mindset, creating a tool still follows the same general...

Toolmaking is one of the most critical and expensive items on the manufacturing to-do list. And because your tool is the basis of your part or product, every decision you make about how your tool is made is, by default, a decision about the quality of your product.

Anything that significant is worth understanding in detail, but how much do you...

Want to make a great product? Make a great tool! (If only it was that easy!)

Tooling is a crucial and expensive item on the manufacturing to-do list. Think about it this way: Each decision you make about the tool is a decision you’re making about your product. But how well do you understand the process of making a tool?

Let’s take a quick look at...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)