You're looking to buy some electronically commutated (EC) motors. You're thinking about speed, noise and energy savings. But if the motors you're purchasing are powering commercial refrigeration units, you need to consider the IP rating as well.

If you haven't given IP ratings much thought, let's take a dive into the details to discover what those seemingly arbitrary numbers can mean to your motor's protection and long-term performance.

Common Threats

EC motors used in commercial refrigeration systems require protection against several hazards, including dust and liquid (in various forms). Here are a handful of examples of common threats to motors in such applications:

- Water from condensation forming on metal parts

- Water from defrost cycles

- Melting built-up ice

- Water jet spraying during washdown

- Dust particles

While certain measures can be taken to protect a motor against the elements it's subjected to in a commercial refrigeration application, the best way to ensure protection and consistent performance is to opt for an EC motor with a higher IP rating.

Read More: Solving the Problem of Motor Protection from Moisture, Water and Dust in Commercial Refrigerators.

IP Ratings: What are they and what do they mean?

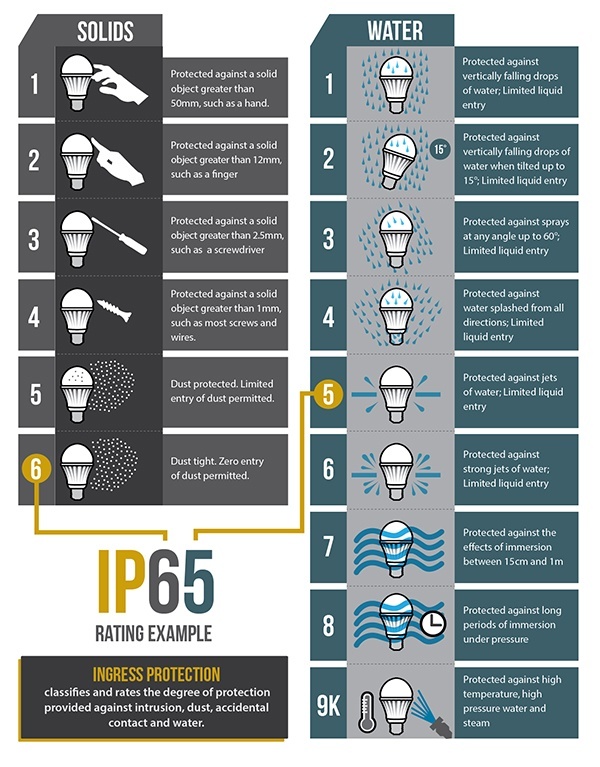

The ingress protection (IP) rating code is an international standard (IEC 60529) used to define levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (tools, dirt, etc.) and moisture.

IP ratings are represented by two digits. The first number indicates the object's protection rating against solid foreign bodies (like dust, tools and body parts). The second number represents the degree of protection against moisture, from drops of water to total submersion. The higher the number, the better protected the equipment will be.

The chart below, courtesy of superbrightleds.com, outlines the specifics of each numerical rating.

Okay, you can see the differences on the chart, but you might be wondering: what's the bottom line?

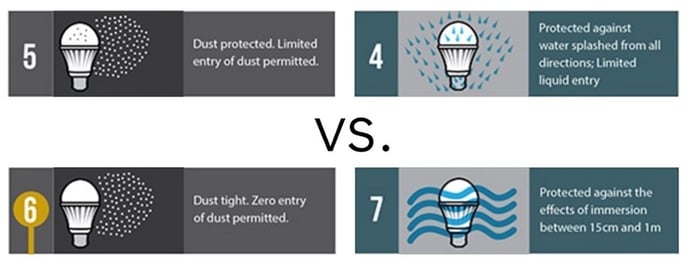

Here’s a real-life scenario: Let's say you have two refrigerated display cases in your store. One is outfitted with an IP54 motor, while the other is powered by an IP67 motor. These ratings have major implications for each motor's level of protection, durability and longevity.

Although IP54-rated motors are very common in these types of applications, they allow dust entry, are only protected against splashing water (not immersion) and allow limited liquid entry. Such conditions put these motors under constant stress and ultimately shortens their lifespans.

The IP67-rated motor, on the other hand, is dust-tight and can tolerate short periods of immersion with no liquid entry. Sounds a lot healthier for your motor than the scenario above, doesn't it? This means your motor won't be threatened by washdown – so you end up with a squeaky clean refrigerated case and no motor damage. Win-win!

It’s pretty clear that the benefits will certainly outweigh the costs if you choose an IP67 motor over something like an IP54 motor, and your IP67 motor will be around a bit longer. How can we be so sure? Because water ingress is the no. 1 source of motor failure in commercial refrigeration systems. Your best bet is to choose a motor that is well protected against liquid entry, period.

To learn more about EC motors check out this post on the Basic Guide to EC Motors, and click on the download below for a free EC Motors case study:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)