When designing a product, considering what happens after its demise will soon become as important as its performance. How to design for the end of a product's life will be guided by the nature of the product, how long it is expected to be used and its recyclability.

Incorporate sustainability efforts into your product design after a preliminary concept has been developed, but prior to finalizing details for production. Typically once the production-ready design has been completed, the costs associated with making design changes present a barrier to improving the product's sustainability. Be sure to work this into your design process and schedule.

Now let’s take a look at some important factors to consider when designing sustainable products for recycling by the end user.

Ease of Disassembly

One of the first factors to consider is the ease of disassembly. If deconstructing a product is a major challenge, users will be discouraged from recycling components and will simply trash the product instead. Make it easy for them! Humans are simple creatures – they like convenience.

Tips for Making Disassembly Easy

- Use fewer parts

- Use common parts

- Reduce the type of number of fasteners used in an assembly

- Use common fasteners that don’t require specialty tools for removal

- Avoid using glue or other adhesives if possible

- If you must use glue, consider a soluble adhesive for easier disassembly

- Include disassembly instructions with product

- Post a disassembly tutorial video on YouTube and share via social media accounts

An added bonus to easy disassembly is that if the product malfunctions or breaks, the user is more encouraged to take the product apart and replace one component rather than tossing the entire unit in the garbage and replacing it. Repairing is much more sustainable than replacing, so you should strive to make repairs painless for the consumer.

Ease of Recycling

As mentioned above, people like convenience. If recycling your product isn’t convenient or obvious, chances are it will end up in a landfill. Remember: Recycling is not intuitive for some consumers. Don’t forget to remind them! And for those consumers who highly value sustainable products, make it clear that your company shares those values, and your products are designed with the planet's best interests in mind. Your potential customers want to see this information off the bat -- they will not search for it. Interact with propspects and customers through your website, social media accounts and other online media platforms like YouTube.

Tips for Making Recycling Easy

- Use clearly labeled and commonly recycled materials

- Avoid paints and other coatings on plastics to avoid contamination

- Spell out any special recycling instructions

- If product is difficult to recycle (like polystyrene), recommend a recycling center that accepts this product

- Include detailed recycling instructions and information on your website

- Remind customers to recycle via your social media accounts

- Provide lists of local recycling centers in each state or region

- Teach customers how to properly pre-sort materials before arriving at recycling centers

Product materials will face one of the following outcomes at the end of their lives:

- Recycling – Waste is converted into reusable material

- Downcycling – Product is converted into new materials or products of lesser quality and reduced functionality

- Example: Paper is shredded and used as packaging material

- Upcycling – Reuse of discarded objects or materials to create a product of higher quality or value than the original

- Example: Soda can pop tabs are transformed into a purse

- Remanufacturing – The rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts

- Example: Auto industry reuses engine blocks

- Remanufacturing can save money and prevent waste almost entirely

- This closed-loop lifecycle is the ultimate goal when designing a product

Extended Producer Responsibility (EPR)

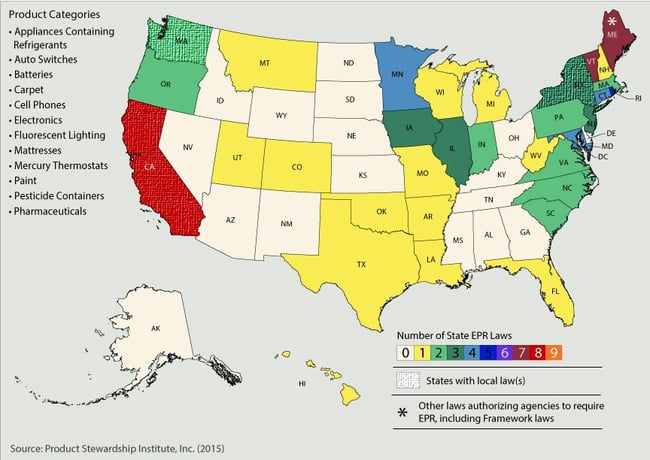

In some countries, and within some product categories, manufacturers are held responsible for the entire lifecycle of a product. This includes recycling and take-back programs to ensure that goods are properly disposed. This concept, called Extended Producer Responsibility (EPR), was introduced in 1990 by Swedish professor Thomas Lindhqvist.

The US has passed a handful of EPR laws at the state level. California currently leads the country in the number of EPR laws passed. Read more here.

Here is a great reference for more on how to design sustainable products for recycling: Design for Product Lifetime by Autodesk Sustainability Workshop.

Related Posts:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)