If you’ve looked around websites for contract manufacturers (CM) or manufacturers in general, you might have seen the phrase “engineered products.” Maybe you’ve even thought, “What’s an engineered product?” After all, isn’t everything that’s made an engineered product of some type?

While it can be a catch-all phrase, we define the term “engineered products” to refer to “the division (of our company) where we manufacture complex, critical-to-function components, sub-assemblies and complete products consistently, to world-class quality standards.”

Broken down in a more generic way, the phrase means a ‘designed product with specific or custom requirements’ versus a commodity-type product. It’s the difference between a plain plastic click-type ballpoint pen versus one with an irregular shape and the capability to click into four different color inks.

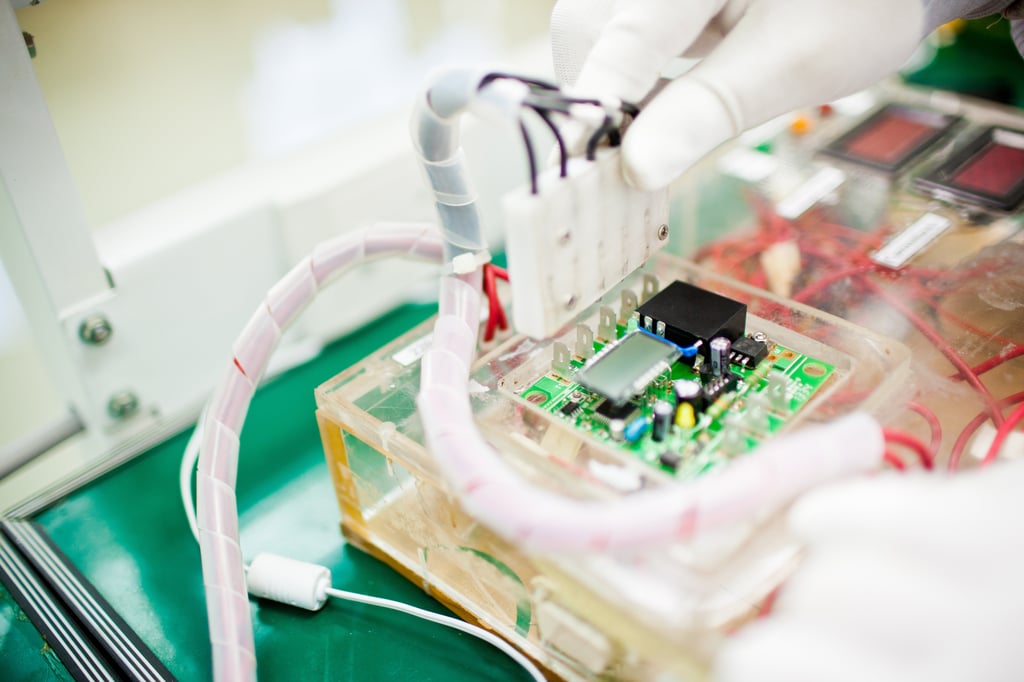

For example, a CM might produce printed circuit boards (PCBA) for assembly in other products. Or perhaps they’ll make electromechanical devices specifically designed for the health/beauty sector on the one hand, the HVAC industry on the other. Maybe the CM produces a plastic housing for an electronic device, and then turns around and creates another plastic housing which includes a motor. The possibilities are as varied as the number of products.

Okay, now we know what they are, what are engineered products made of? Obviously, the material has to suit the product/component requirement but materials for the products mentioned above typically include:

- Plastics (Injection molded or other)

- Electronics (PCBA)

- Metal (Casting, stamped, extruded)

- Rubber (Compression molded)

Most CMs simply build the product from the customer’s designs. The company’s engineering department assesses the designs to make sure they can be manufactured efficiently — that’s part of design for manufacturability (DFM). They test the product in production to meet customer specs. However, some CMs offer design services throughout the process or assist with prototyping. It’s really up to the customer to decide.

So that’s a simple explanation. Basically reach out your hand in any direction and you’re probably going to interact with an engineered product.

For more about engineering and DFM check out these blog posts:

- 5 Factors that Affect Design for Manufacturability (DFM) [Video]

- Can Increasing Design Tolerances Cut Your Production Costs?

- How Small Design Changes Can Affect Product Development Pricing

And if you're looking for more DFM info, download this FREE checklist to help you find the ideal DFM partner.

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)