Show of hands...Who likes waiting? Standing in line? Being put on hold?

No one.

Waiting is no fun. It feels like such a waste — a waste of time and resources. That's one reason Amazon was able to create a subset of customers willing to pay $10 a month for two-day shipping. It's also why they can charge a premium for 1-day or even same-day shipping. No one likes to wait.

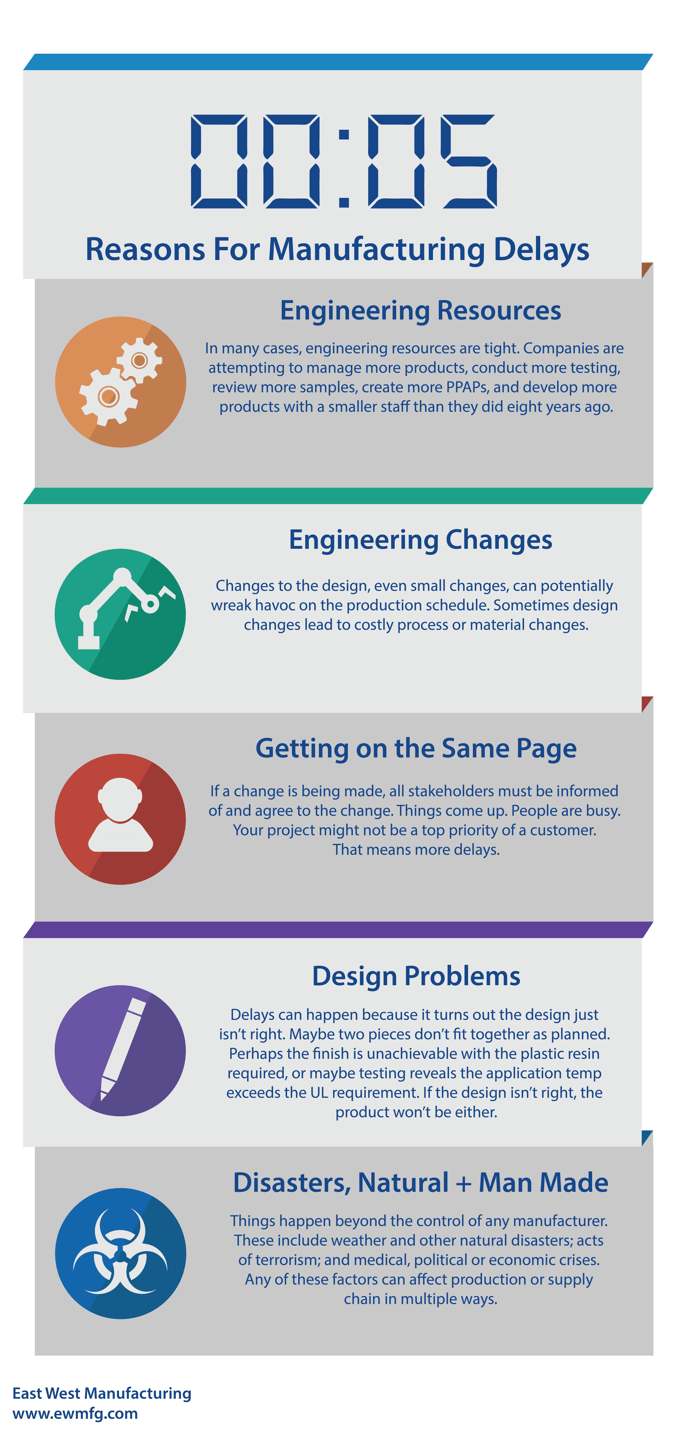

Nevertheless, manufacturing delays are inevitable. Our nifty infographic tells the story:

None of these reasons seems very satisfactory when you're experiencing but here are a few tips for making the best of a 'meh' situation.

Engineering Resources | Be Realistic

Do you have an project engineer assigned to your project? Ask them where the project stands. Do they need any more information from you? And get their best and honest estimate of when you can expect your project to move forward. Once you have that information written down, leave it alone. There is nothing more you can do. As sales genius Zig Ziglar used to say, "You can't climb a fence leaning toward you and you can't kiss a girl leaning away from you." Be patient. Be realistic.

Engineering Changes | Tweaks Add Up

Little acorns become oak trees, and sometimes little changes create a large ripple effect in the product development schedule. Head's up: Changes can also impact pricing.

Read more: How Small Design Changes Can Affect Product Development Pricing

Getting on the Same Page | Checking All the Boxes

A delay on the front end, is better than confusion on the back end. Better to be certain that everyone is aware of changes and that you have that in writing.

Design Problems | Getting It Right

Do you want it right or do you want it now? (I know...how about both?) Sometimes a finding a flaw at the last minute means a slow down, but that's when you have to remind yourself that it's better for you to find a problem instead of a customer. Focus on getting the product right, not getting it fast.

Disasters, Natural + Man Made | It's a Mad, Mad World

Things go wrong that no one could ever foresee. Natural disasters that can obliterate a supply chain; acts of mischief (hackers) or terror (bombings) that catch you unaware; economic meltdown (remember the response to the Brexit vote?) We often forget how truly linked and reliant we are on each other until disaster strikes. Remember: it might be sunshine and rainbows where you are (figuratively), but thunder and lightning where your supplier is working.

Pro tip: Stay informed about the world. Read newspapers and trade journals to stay abreast of the types things you can prepare for.

Hang in there. We've said it before and we'll probably say it again. Product development isn't for the faint of heart. Control what you can, release what you can't. And if all else fails, watch cat videos on You Tube.

Read more:

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)