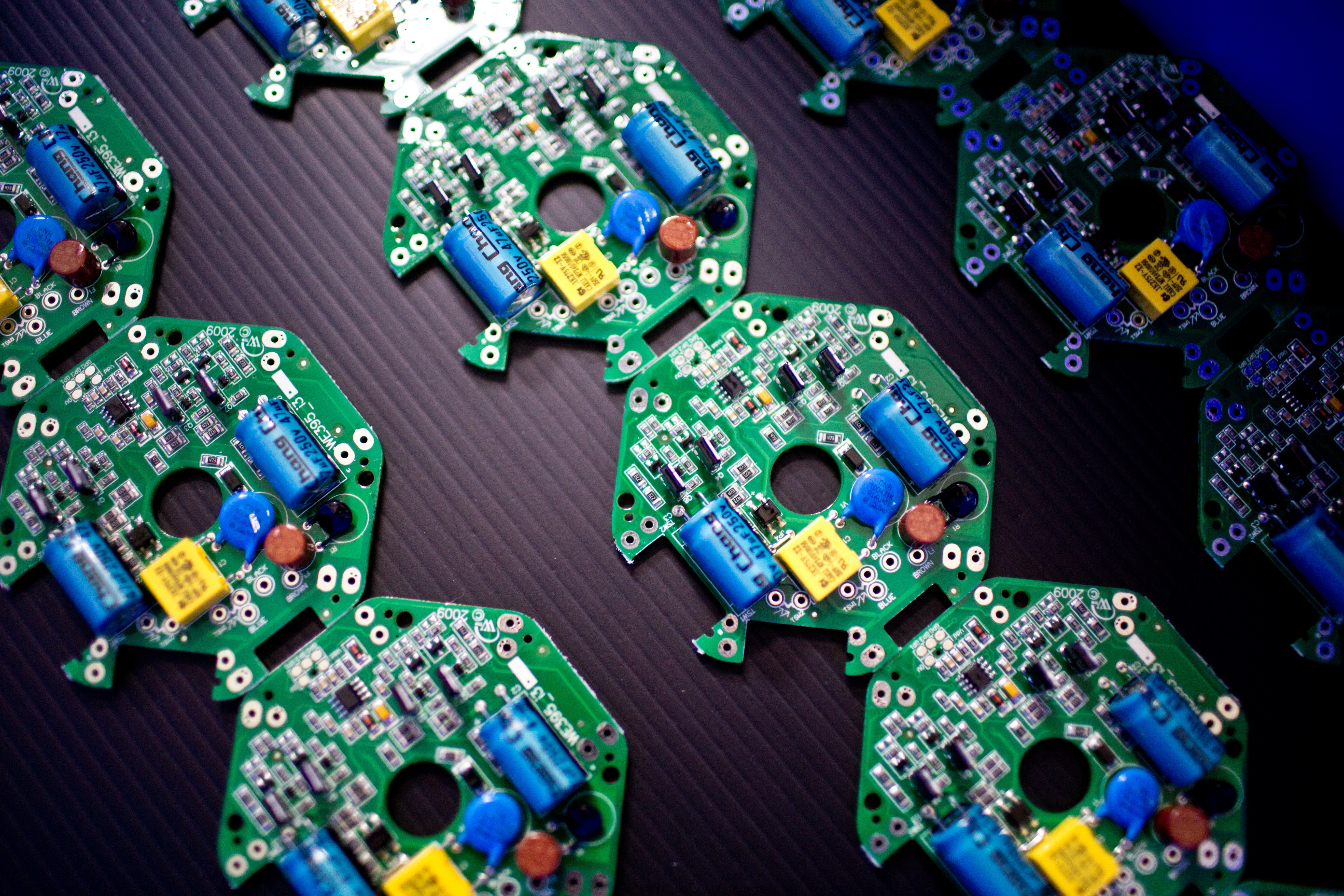

Do you order electronic assemblies that contain long lead time (LLT) components? Nothing is more frustrating than placing a large PCBA order only to find out that a key component has a 180-day lead time, slowing down the entire production process. Why do some components have such long lead times, anyway? Here’s the deal: Factories typically run...

If you thought the new product development process was going to be a walk in the park, you might need to take a look at a survey conducted by Gartner in 2019. The survey questioned CEOs about the success of new product introduction, and the numbers were sobering.

It probably won’t come as a surprise that engineers love their acronyms. If you’re not fully immersed in this world, it can become increasingly difficult to decode what may sound like a foreign language, and while we can’t explain every abbreviation you may come across in one blog post, we’re going to start by discussing the differences between...

RFx Management: Understanding the Difference Between RFI, RFP and RFQ

It's a common mistake among procurement newbies to use the acronyms RFQ and RFP interchangeably. Throw in RFI, and things really start to get hairy. Understanding the nuances that distinguish these different types of requests (for information, proposal and quote) will help you get what you need a little faster and more easily, and that's something...

Manufacturing Location Considerations: Where to Make My Product?

Have you ever wished for an easy, all-in-one-place guide to the most cost-effective locations for specific manufacturing processes? Maybe you’re thinking, “No, but now that you mention it…” 😊

I have this image of a sourcing manager talking to a supplier with the conversation going something like this, “I don’t have extruded aluminum right now, but what I do have are a very particular set of skills; skills I have acquired over a very long career. Skills that make me a nightmare for people like you. If you let me have the aluminum that...

When you work with engineers prepare yourself for a heaping helping of acronym soup! You’ll hear it all: PCB, PCBA, DFM, FMEA, PO, IP and of course the BOM, which stands for Bill of Materials. And while all those other acronyms are highly important to the product development process, it’s the BOM that gets you on your way.

You’ve found your new manufacturing services provider! YAY!

But that manufacturer is only as good as its weakest link. It’s up to you to know all about the companies supplying your manufacturer. It’s time for supplier evaluations, and we've got a list of questions for a supplier evaluation checklist.

Lower cost. That's the goal of every sourcing or procurement manager, right? Well, it's certainly one goal. But how is cost measured? How great is a cheaper part or component if you can't get it on time or it isn't up to spec?

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)