You’ve done your research and have decided it is time to switch to a new supplier. Maybe you are looking to reduce your risk by moving out of China, or perhaps you'd like to gain a competitive advantage with new pricing, or you’re considering the need to diversify your supply chain. Whatever your reason may be, moving production doesn’t have to be...

Companies are continuing to search for alternative low cost countries to manufacture their products to lessen their reliance on China as rising labor costs and persistent disruptions continue to affect the entire supply chain. Among other Asian countries, Vietnam is garnering significant attention from C-suites and has seen a massive jump in...

It is the pandemic that has shocked the world. Though health experts had been talking about a global pandemic for years, lack of adequate planning and global reliance on China’s manufacturing prowess allowed COVID-19 to unveil major vulnerabilities in today’s supply chain trends.

While we have our own theories on what the post-coronavirus world...

We've written a lot about protecting your facility and processes from cyberattack. As these incursions continue to escalate, in number and in scope, companies of all sizes must address the issue of cybersecurity.

Hindsight is 20/20. We’ve all heard that adage. But what if hindsight could become foresight?

It's no secret that labor costs are rising in China, and talk of alternative manufacturing locations continues to grow. While some operations are returning to the US and Europe, others are staying in Asia, and India is rapidly attracting more business. Yes, there are labor and raw material advantages, as well as increasing infrastructure, but...

Do you remember the scene in the movie Father of the Bridewhen Steve Martin’s character George Banks goes nuts over the number of hot dogs in a package versus the number of buns in a package?

No?

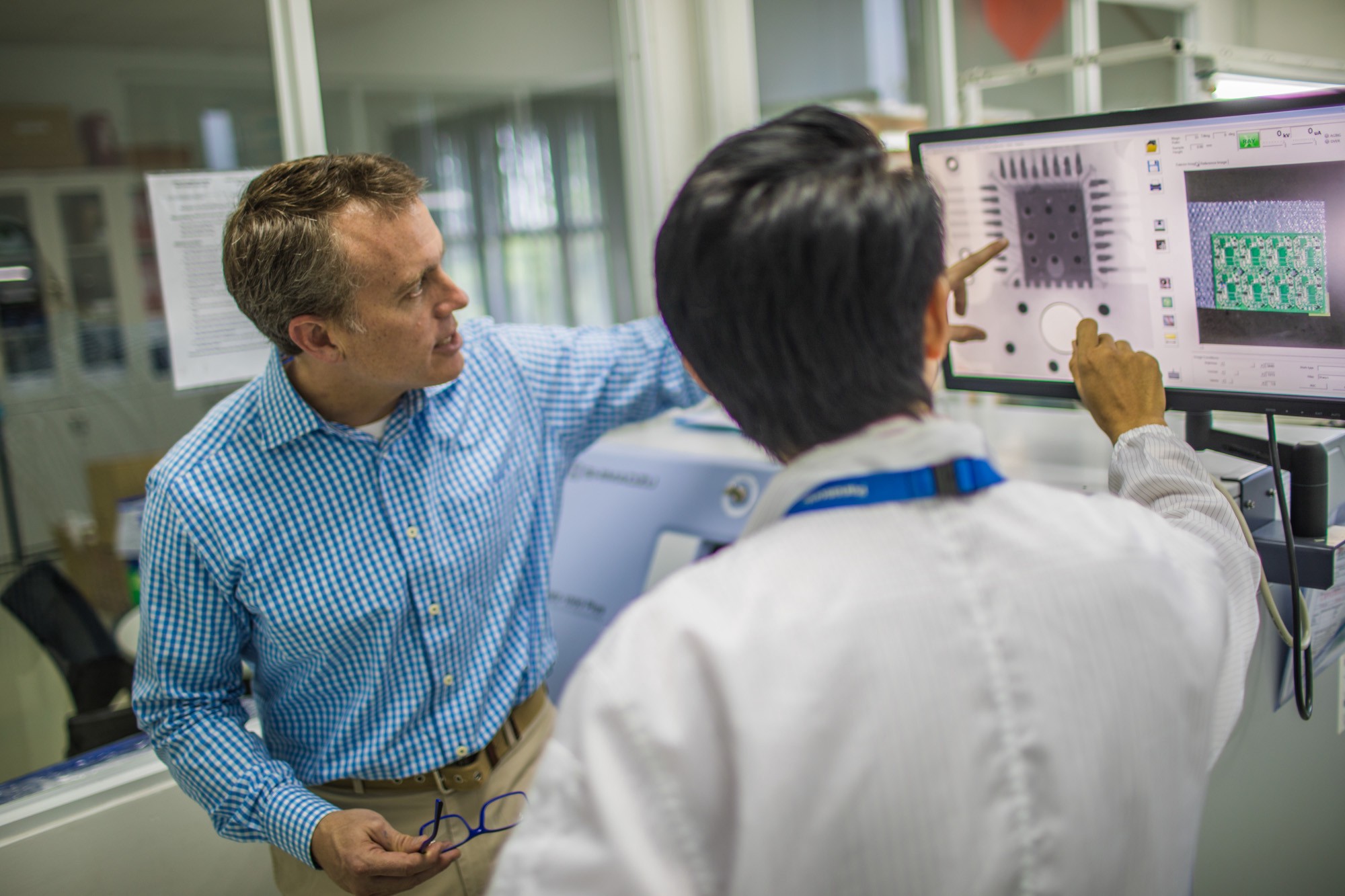

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. The acronym DFMA (Design for Manufacturing and Assembly) is sometimes used interchangeably with DFM.

You don't need to be part of the manufacturing industry long to learn it has it's own native language with no shortage of acronyms. BOM, CBOM, EBOM, MBOM -- it can get confusing very quickly, but we've got you covered with this dictionary of the most commonly heard terms to help you navigate your way through the product development process.

Let me guess – you’ve designed an amazing product that you want to manufacture in China, but you’re worried that a cheaper version of your product will appear on Alibaba in a month. Who wants to spend the R+D dollars to then have their intellectual property (IP) stolen in a flash? Taking your IP to China will prove much smoother (and less risky)...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)