When it comes to choosing the right plastic for your product, there are an overwhelming number of options. The first thing you need to narrow down is this: thermoset or thermoplastic? Your decision will be largely based on your product's specifications and final application. Let's examine the differences between the two, the pros and cons of each,...

Thermoset vs. Thermoplastic: Which is Right for My Product?

Working with engineers is very similar to working with military personnel in that to communicate effectively, you need to learn acronyms quickly! Follow along:

An ID firm can create the concept and DS (or DMS) produces the drawings you need for a CM to manufacture your product. OEMs work with CMs to bolster their supply chain. If your OEM produces...

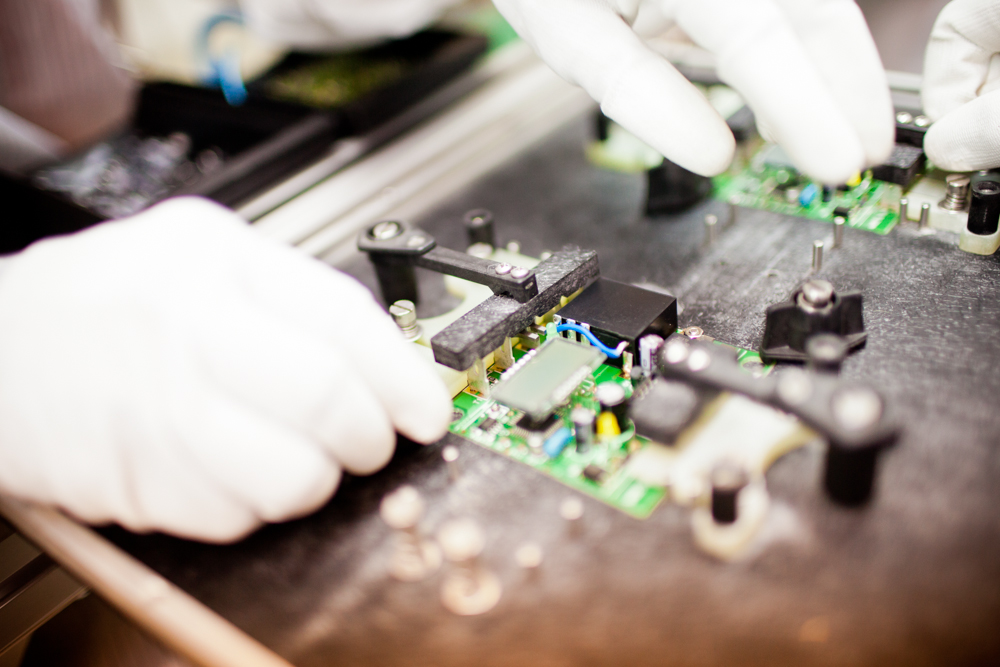

Do you order electronic assemblies that contain long lead time (LLT) components? Nothing is more frustrating than placing a large PCBA order only to find out that a key component has a 180-day lead time, slowing down the entire production process. Why do some components have such long lead times, anyway? Here’s the deal: Factories typically run...

Reducing costs is an ongoing task for every company, but what if I told you that you could save money without having to change a single millimeter of your product?

You’d probably be thrilled.

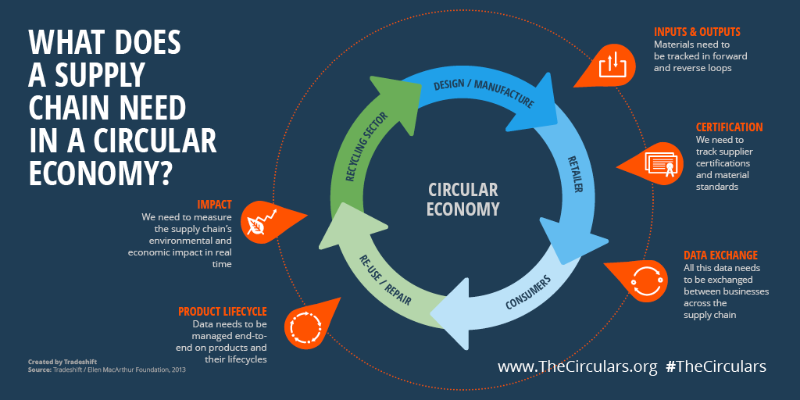

In this day and age, it's simply not enough to state a claim of corporate social responsibility. We need to enact change. A company concerned with sustaining its marketplace must take action, and one practical jumping off point is supply chain analysis. Aim to transform your supply chain from a linear (take-make-dispose) model to a circular...

It's no secret that labor costs are rising in China, and talk of alternative manufacturing locations continues to grow. While some operations are returning to the US and Europe, others are staying in Asia, and India is rapidly attracting more business. Yes, there are labor and raw material advantages, as well as increasing infrastructure, but...

Do you remember the scene in the movie Father of the Bridewhen Steve Martin’s character George Banks goes nuts over the number of hot dogs in a package versus the number of buns in a package?

No?

Setting up an engineering lab may feel like a mammoth task, but the most important thing to keep in mind is that safety should always be your top priority. Protect your employees and keep your engineering lab running efficiently with the following 10 lab safety tips.

At some point the leadership team of a company that manufactures a product, sits around their conference room and asks themselves the million-dollar question, “Should we consider moving production offshore?”

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. The acronym DFMA (Design for Manufacturing and Assembly) is sometimes used interchangeably with DFM.

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)