Third party testing and certification is one of the most important and expensive decisions you'll make in the product development process.Certification marks — whether UL, ETL or some other entity — demonstrate that the testing facility has tested samples of the product and found that it met that entities' requirements. The mark guarantees the...

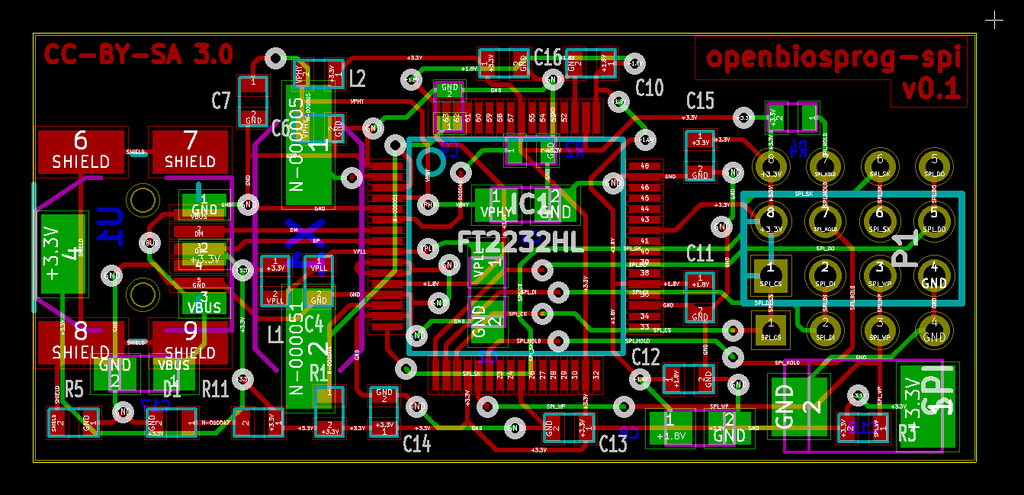

Our engineers work with a lot of Gerber files. You probably know what that means, but just in case you don’t, Gerber is the file format for submitting printed circuit board (PCB) file designs to a PCB manufacturer. When you’re developing a product that includes electronics, you will have to supply Gerber files along with all your other product...

You’ve found your new manufacturing services provider! YAY!

But that manufacturer is only as good as its weakest link. It’s up to you to know all about the companies supplying your manufacturer. It’s time for supplier evaluations, and we've got a list of questions for a supplier evaluation checklist.

Lower cost. That's the goal of every sourcing or procurement manager, right? Well, it's certainly one goal. But how is cost measured? How great is a cheaper part or component if you can't get it on time or it isn't up to spec?

Hey, we get it. No one, NO ONE, likes to wait. But there are ways to mitigate the potential delays in ordering electronic assemblies containing long lead time (LLT) components.

Of all the questions we hear, "why did my quote change" is one of the simplest and toughest to answer. The quote changed because of...well...change. But the reasons for the change can be complicated. In fact there might be more than one reason why your quote changed. Let's take a look at some of the factors that can cause an adjustment to your...

Last year we wrote about preparing your company for the supply chain disruptors described in one white paper as a "tsunami of new technology."

No matter the complexity, manufacturers are always looking for ways to reduce the cost of making things, and sometimes they end up with a better product as a result. That process is called value engineering. And yes, it's possible to make a better product through value engineering, especially if you ask a lot of the right questions.

Here’s the scenario: You have a part that you’ve been making and selling but you’ve decided to put it out to quote. You send your drawings package and samples of the part to a contract manufacturer that has a reputation for providing quality engineering support. In reviewing the drawings, the project engineer picks up on a small but significant...

Very few people walk into a store, take an item off the shelf and purchase it without looking at the price. Even if you’re reasonably certain you can afford it, you’ll glance at the label to see how much it’s going to cost. If it’s what you want, and the price is in line with your desire for the item, you’ll buy it. But retail prices aren’t...

.jpg?width=176&height=56&name=MR_associatedNetwork_logo%20(1).jpg)